GENEREX – 30 Years of History

Interview 2012 by Frank Blettenberger - "The BMS Revolutionary" shows the history of the development of GENEREX

From an interview for a British battery magazine in 2012, Frank Blettenberger got his nickname as the "BMS revolutionary" - a few years before this name and his vision actually became reality with BACS.

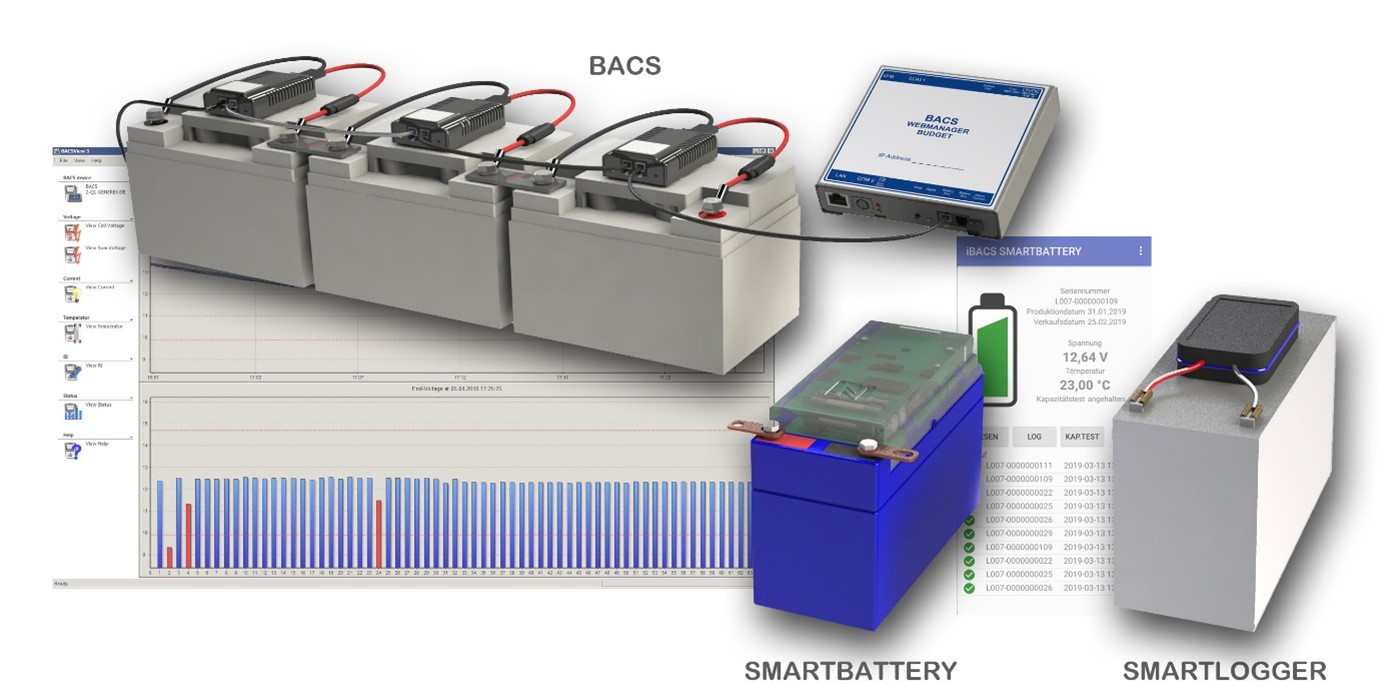

BACS and the new EU patented “SMARTBATTERY / SMARTLOGGER” are a revolution and the basis of GENEREX’s exponential growth over the last 30 years.

Read the story of GENEREX from humble beginnings as a one-man show to a multimillion-dollar company and industry leader.

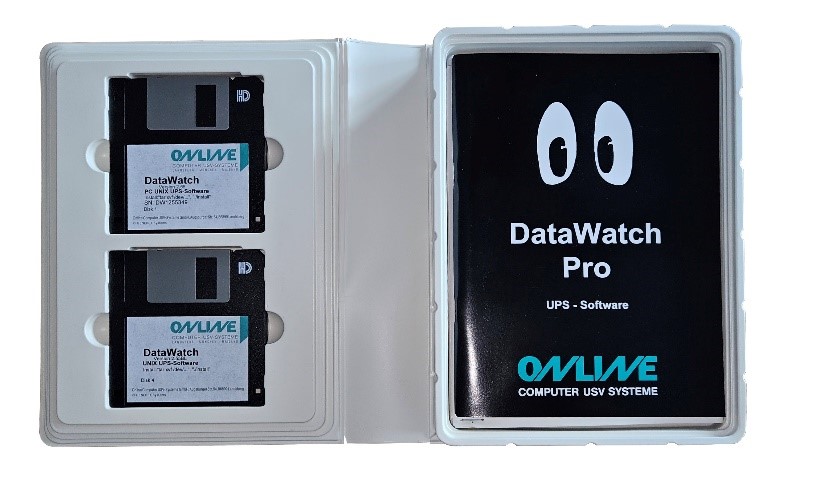

The revolutionary story begins in 1994 with the founding by Frank and Peter Blettenberger in Hamburg, Germany. As an IT software company, GENEREX brought its first UPS shutdown and monitoring software to the just beginning market of UPS systems in networks, at that time still based on “MS-DOS”, “NOVELL”, “IBM OS/2” and various new OS under the name “UNIX” and the brand-new product “Windows” from a then unknown company “Microsoft”. GENEREX sold the first 1,000 software licenses to the German "ONLINE USV-Systeme" based in Munich, at that time delivered on 5.1/4 floppy discs and magnetic tapes, later 3.5" diskettes. The first GENEREX customer is still a customer 30 years later and under the memorable logo with the eyes, ONLINE is one of the largest UPS dealers in Germany.

The next logical step for the company was to produce its own network cards to transmit UPS data via various network protocols, at that time starting with the "Simple Network Management Protocol" (SNMP). To this day, UPS network cards in Europe are simply called “SNMP cards”, a standard that Frank Blettenberger had established in the UPS industry at the time and which still shapes the market in Europe today. The different classification of UPS systems in Europe and the USA that is still visible today comes from this time - in Europe, UPSs belong to IT using SNMP as a protocol, in the USA, UPSs belong to building management using bus systems such as Modbus, BACnet, etc.

In 1999, the Chinese imports of such network cards proved to be unreliable and GENEREX's strategy of breaking away from Asian partners and only producing themselves was based on this early phase of network products for UPS devices. GENEREX invested heavily in its own network card, called “CS121,” which first came onto the market in 2001. The CS121 was a milestone in the development of GENEREX and the beginning of a long career of “CS1x1” products, which to this day forms the backbone of the European UPS industry. Frank Blettenberger recognized early on that companies in the critical power supply sector were prepared to pay more for a quality product made in Germany with qualified customer service and support than the usual Chinese products on the market. This evolution to 100% depth of production culminated in GENEREX today launching the 4th generation of its network products under the name “CS141 HW161”, the core product of all other GENEREX products with network connectivity and one of the few with certified network security according to UL 2900 -1 on the market.

But the software products “UPSMAN”, “RCCMD” and “UNMS” have also captured a significant market share in the EU and communicate with almost all UPS products from 1992 to 2024 that are used in Europe.

The shortcoming of most UPS products to this day is their battery - that is the Achilles heel of every UPS.

The logical next step was to develop a battery monitoring system to complement the portfolio of UPS management systems. This is how GENEREX began to enter the world of battery monitoring systems “BMS” in 2003. However, it soon became clear that battery monitoring alone does not help solve the UPS battery problem. State of Health (SOH) and State of Charge (SOC) were a hurdle that GENEREX was unable to overcome for a long time, as impedance - the basis for most battery health measurements - although theoretically ideal for such measurements, was at that time in high voltage circuits the most important for UPS are typical, was very inaccurate. So extremely inaccurate that to this day customers refuse to accept impedance as the reference for battery health.

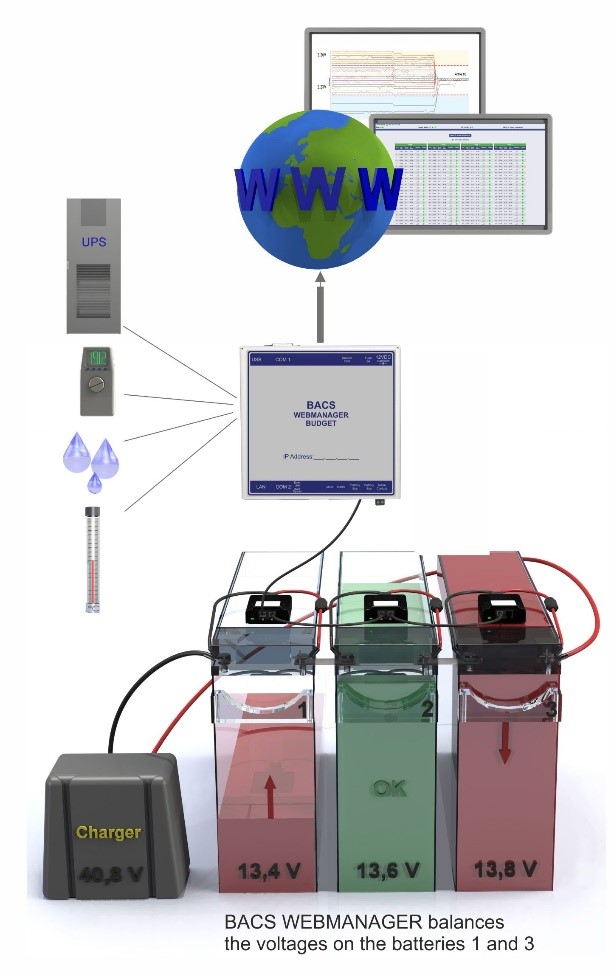

In fact, impedance is still the best method for evaluating the battery, but interference from the UPS end devices themselves and the extremely high resolution of the measured values required have actually made every battery monitoring system on the market unusable to this day. The impedance measurements are displayed, but there was no connection to the actual battery health and customers lost interest in battery monitoring. Battery monitoring had no added value for the user; the batteries were unstable with or without monitoring and were a constant annoyance for the user. So GENEREX first had to find a solution to the inaccurate impedance measurement. After many tests, the collaboration with EFFEKTA, an industrial UPS provider from Germany that is still successfully operating on the market, has shown that adjusting the voltages within a battery string to identical voltage levels solves the problem. Under the name “Equalizing” - which technically corresponds to the balancing that can be found in every lithium battery today - the revolution began in 2004 with the “BACS” - “Battery Analysis & Care System” of the 1st generation with an improved impedance measurement “Equalizing”.

But it quickly became clear: the enthusiastic customers were most interested in the amazing control of the voltage of each individual cell! All cells in the system were suddenly perfectly balanced and there were no longer any deviations from the ideal value. That was exactly the reason for the introduction of balancing - but with the aim of improving impedance measurement.

This balancing technology was first seen in the development of lithium batteries and was early adopted by GENEREX for lead-acid batteries in high voltage ranges for UPS systems. After several years of testing with customers, the technology was also transferred to NiCd, later to lithium ferrophosphate (LiFePo4) - and, more recently, to lithium titanium oxide cells (LTO) and today covers the entire range of battery chemistry types be used in emergency power systems.

The fact that “balancing” - actually introduced as a solution for impedance measurement - had such a positive “side effect” on the service life and reliability of UPS batteries made the world of lead-acid batteries sit up and take notice a few years later - the market success of BACS began with this “revolutionary” technology of balancing.

Thanks to balancing, the batteries became significantly more stable and had a demonstrably higher capacity and in some cases even achieved the “design life” (lifetime specification from the battery manufacturer) in a UPS application - something that no battery in UPS operation had even come close to achieving before the introduction of balancing! Suddenly there was an explanation and at the same time a solution for batteries that could only achieve a lifespan of 50-60% in UPS operation without balancing!

In fact, BACS users have made the system a success! The names of the first highly satisfied customers read like a Who's Who of the Industry Elite. Airports and air traffic control in the civil and military sectors were the first customers of BACS, soon followed by the American banks and their data centers, from where word of the new BACS product spread to the rest of the world. Today, almost all of the top 500 companies in the Western world are satisfied users of BACS; hardly any data center built today can do without BACS. Battery monitoring has had its day, but battery management has become an indispensable part of the world of data centers.

Other industries also began to be interested in BACS, mainly from the military sector or from particularly critical application areas of batteries such as nuclear power plants, ship technology, tunnel construction, and the oil and gas industry. What these critical applications have in common is that the energy content of the batteries is less important than the stability and safety of the batteries. This is exactly where the new lithium cells emerging from Asia were unable to displace the established batteries. If safety is more important than battery life - then the reliable lead battery remains the energy source for this market!

It wasn't just the issue of safety that caused a renaissance, a return to the "old" lead battery technology, the first negative experiences with lithium cells were also seen on the market after a few years. The development of pure lead AGM batteries, which functioned stably even under high temperatures, showed lithium cells their limits, the gap between lead batteries and lithium narrowed: It quickly became clear that lithium cells were only theoretically better for UPS operation were suitable as lead batteries. To date, lithium cells have to be greatly oversized in order to prevent the cells from reaching critical temperature ranges or charge states. Everyone knows the problem of electric cars burning when the battery is empty - and when the battery is overfilled... Such oversizing is not necessary for lead batteries. This caused disillusionment for UPS customers who were initially enthusiastic about lithium. The fact that BACS was able to further narrow the gap between lithium and lead batteries - through more capacity and longer service life and stability of the old lead battery technology - has meant that the market share of this battery technology is no longer shrinking but is actually growing! The new lithium-based cells turned out to be not ideal for the high safety requirements of customers and created a “market niche” for the supposedly outdated lead or NiCd-based batteries. To this day, the battery technology, which is considered outdated, is the safest battery solution for UPS systems or emergency power devices on the market - and the cheapest!

The data center market now forms the largest share of the battery market that BACS serves. Google, Facebook, Microsoft etc. - thanks to “Big Data”!

After many years on the market and with more than 3.4 million BACS systems installed, battery management has also established itself among battery manufacturers - at least where the customer specifies BACS. With the new EU BattG 2024, many other battery applications will certainly require a BMS and GENEREX hopes to continue riding this wave of success together with its customers.

After 30 unsuccessful years of battery monitoring the breakthrough for this sector began with BACS in 2012: Battery management is now one of the fastest growing markets in the world and BACS with “Balancing/Equalizing” is the “game changer” in this industry.

The success of BACS is undeniable today, but our Frank was already thinking about the next technical solution the market might need. His new idea led to a European patent in 2024 - called "SMARTBATTERY" and "SMARTLOGGER" - in principle the first "battery passport" that meets all the requirements of the EU BattG 2024 - only presented and produced for the first time in 2014 - long before the EU BattG.

The idea for his new patent is based on one “intelligent battery” – the “SMARTBATTERY” which already has all the data from the “cradle to the grave” built in”, in the form of a “chip solution”. The new contactless standard “Near Field Communication (NFC) is ideal for this because of its low power consumption and data security. "We want to set a standard for stationary battery management and make it part of the IT management products, like UPSs are today," said Frank Blettenberger back in 2012. Today, in 2024, the new EU battery law describes exactly that, what GENEREX had developed years before and has now been patented just in time for the EU BattG! If there is a product on the market today that can meet the regulations of the new EU Battery Law 2024, it is GENEREX BACS and the patented SMARTBATTERY/SMARTLOGGER!

The person - Frank Blettenberger

Successful business people do not always set out to build large companies or be successful in a purely entrepreneurial sense. Rather, they tend to do their work with passion - and be very good at it. Over time, these qualities bring their own rewards - whether intended or not.

Frank Blettenberger is a typical example of this. He is the founder and majority shareholder of GENEREX, the specialists for battery management and networks of critical power supplies based in Hamburg, Germany and Cornelius/Mooresville NC, USA. The company is 100% family-owned, but Frank Blettenberger and his brother Peter play an inconspicuous role. The fact that for many decades he referred to himself only as the company's "technical director" - and not as CEO or CTO - perhaps sums up his attitude to his business and corporate strategy: for him, it's all about the technology. Quote "If we bring the best products possible to market, the rest will take care of itself," he told Battery International magazine's Wen Jenkins in a 2012 interview.

GENEREX is today one of the leading manufacturers of UPS connectivity products and battery monitoring systems for emergency power devices but is still a “hidden champion” with little awareness in the market. The reason for this is GENEREX's business model– exclusively in business-to-business and OEM business for 30 years never directly with end customers, but always under the brand names of its partners who market its technology. This ensures a strong bond between partners and deep integration into their own products and will continue to be GENEREX's strategy in the coming years.

Wyn Jenkins, freelance journalist for various industry trade journals in Great Britain, spoke to Frank Blettenberger, the company's founder and current president, about the development and ambitions of GENEREX and the long journey since 1994 for a specialist article in the magazine "Battery International".

Back to