BACS for ATEX-Zone 1

BACS ATEX certified module of device group II for zones 1/21 and 2/22

Available now!

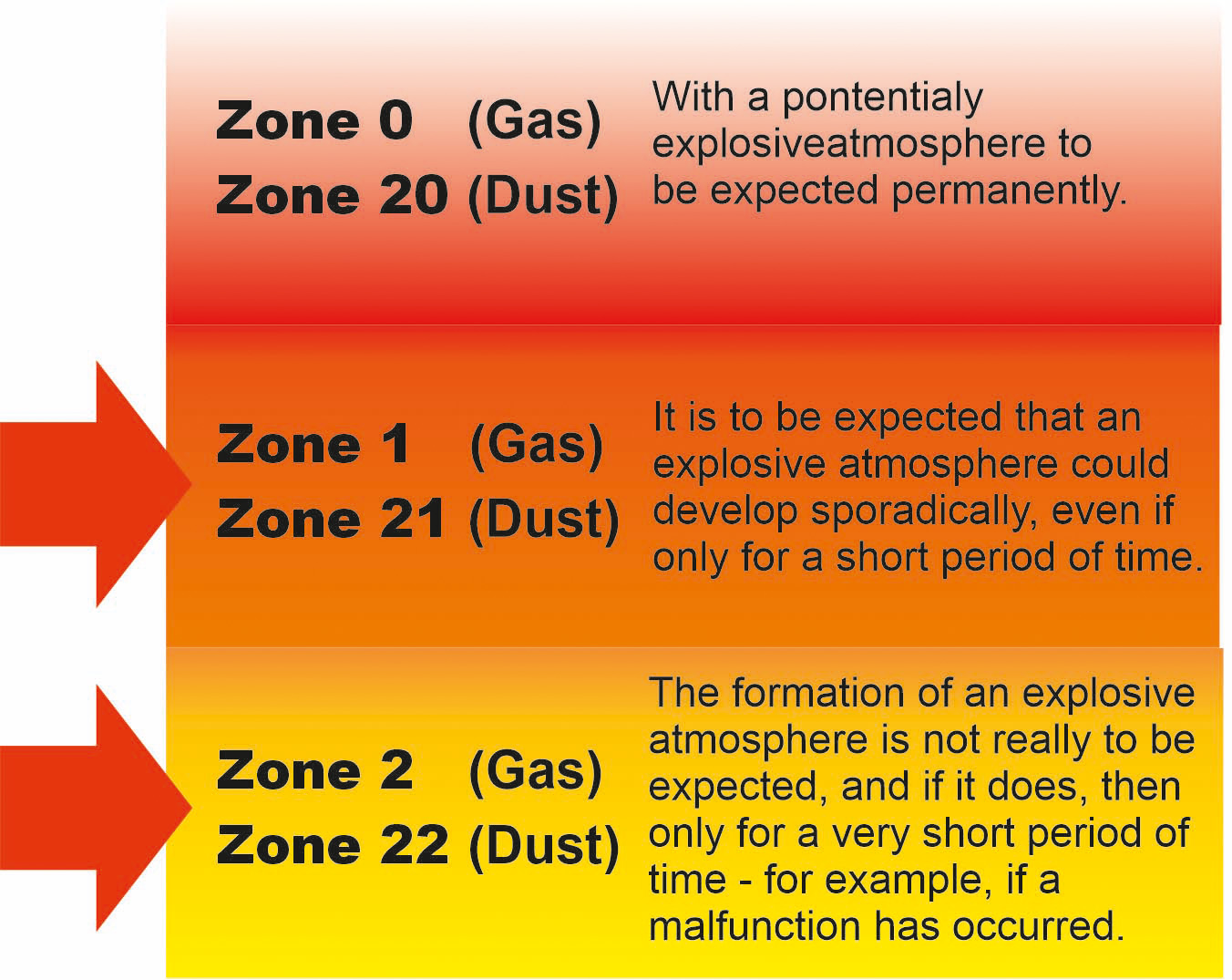

In the oil and gas industry, various products with different ATEX certifications are used depending on the application and environment. While in some areas where explosive atmospheres cannot occur, certification is not required at all, in other areas products for ATEX zones 0, 1 or 2 must be used, which is associated with considerable additional costs.

NEW

GENEREX is the only manufacturer to offer this a BMS for ATEX zones 1/21 and 2/22!

The proven BACS C modules of generation 3 have been built since 2010 and have been sold more than 3.4 million times. This makes BACS the best-selling battery management product for critical power supplies and has proven its robustness and reliability millions of times. Thanks to a special protective housing with up to 3 BACS modules and the use of special cables, BACS is for ATEX group II certified and can be used in zones 1 and 21 or 2 and 22. A flameproof encapsulation according to IEC60079-1 is used as the type of protection. The device is specified for gas group IIC (Typical Gas: Hydrogen) or for conductive dusts such as metal dust or carbon-containing dust. The module can be assigned to temperature class T5 – up to 100°C.

ATEX codes:

Zone 2: II3G Ex dc IIC T5 Gb or II 3D Ex tc IIIC T100°C Db

Zone 1: II2G Ex db IIC T5 Gb or II 2D Ex tb IIIC T100°C DB

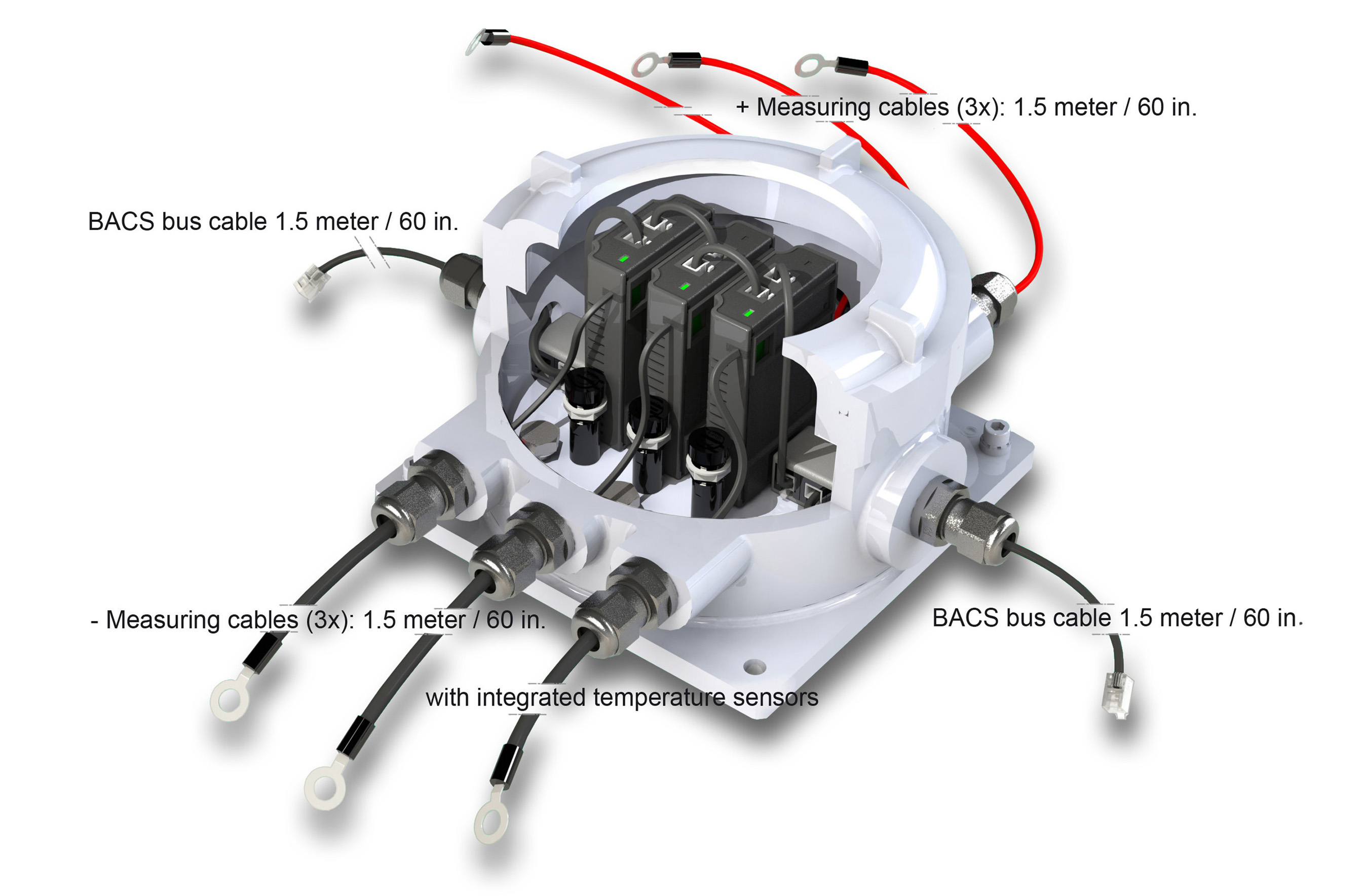

The 3 BACS C modules (standard scope of delivery) are delivered mounted on a base board anchored in the housing and are already connected to one another at the factory. All battery measuring cables (each 1.5 m long) are led out in a gas-tight manner. A temperature sensor is installed in the cable lug of the negative cable measuring cable, which is why the negative cable is slightly thicker than the positive cable. There are 6 high-voltage fuses on the base board (which are otherwise installed in the measuring cables), which can now be easily replaced. In the event of repairs, each BACS module can be individually removed from the base board and replaced with a new one.

All 3 modules have their LEDs pointing upwards, so that you can see their operating status directly through the pane in the housing and can easily reach the addressing switch when programming the addresses. The battery measuring cables are available with ring cable lugs M5, M6, M8, M10 or M12. All cables are halogen-free and suitable for use in potentially explosive areas.

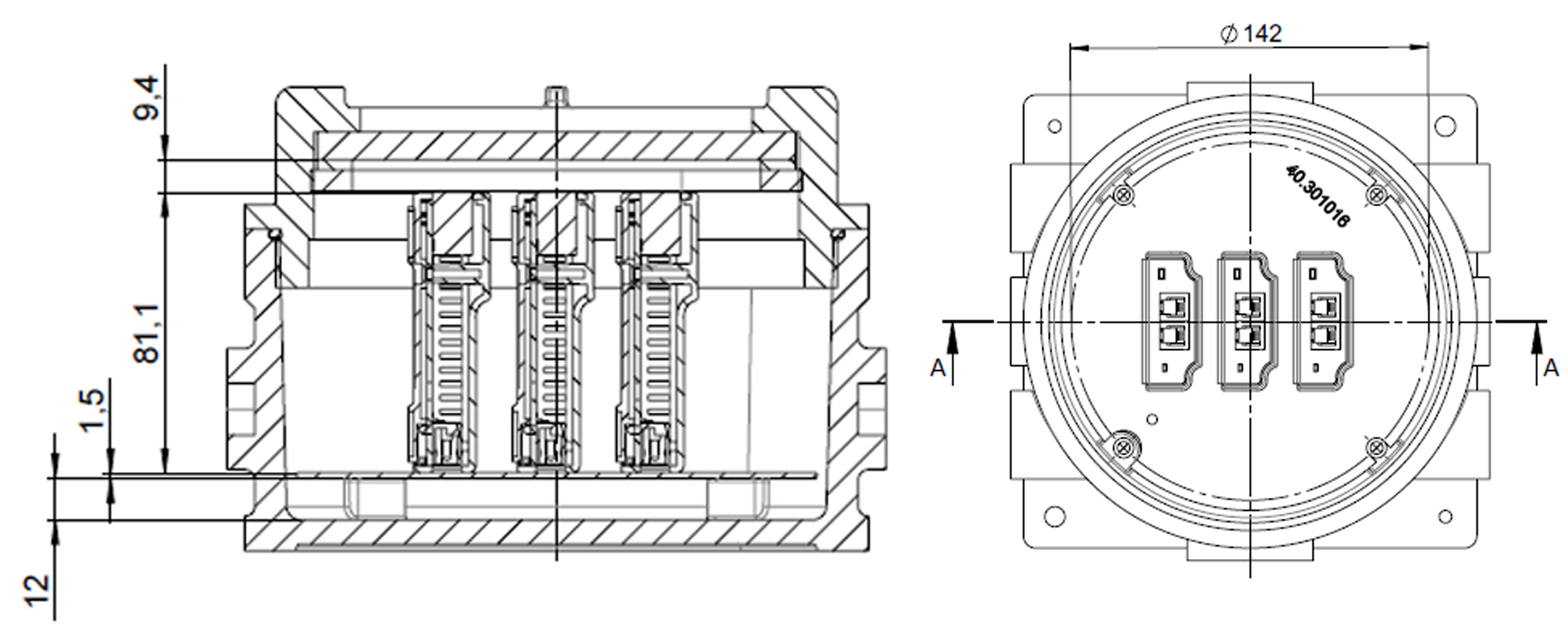

The dimensions in the drawings below are in millimeters. The total height is 146mm. The shape is square, so the width is the same on all sides and is 190 mm.

Easy installation and commissioning, even when retrofitting

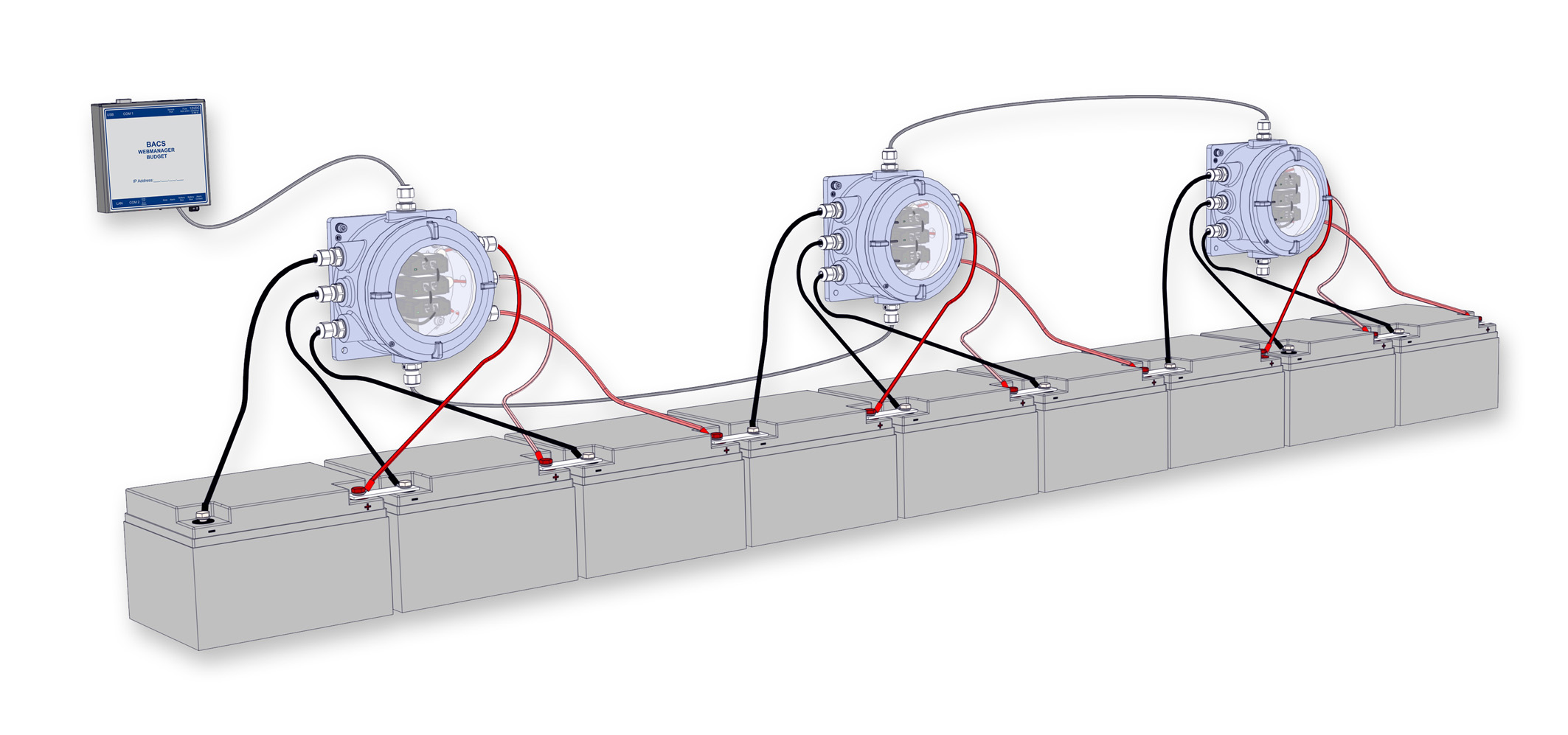

During the new installation, the pressure housing is opened by the installer and the BACS data line is laid between the individual housing modules. Each Cxxex3 module has two EX - certified cable glands to seal the BACS data line in an ATEX-compliant manner after installation work. Since the BACS measuring cables are already pre-installed, all that remains is to connect the batteries and initialize the modules according to a known scheme using the BACS programmer integrated in the BACS WEBMANAGER.

Upgrading and converting existing systems

The design of the new housings for the BACS ATEX solution allows existing BACS installations to be easily and intuitively "upgraded" to ATEX without much effort. The ATEX housing and the associated cables can be delivered in an "unequipped" version - after installation, the existing system modules only need to be "plugged" into the individual ATEX housings and sealed and connected accordingly. In this way, your customer has to Don't sacrifice or throw away existing BACS investment to achieve ATEX certification!

Back to

Next Article