With the SM_H2_LC, a new sensor is launched especially for the European market, which can specifically detect hydrogen concentrations and report them accordingly. The multi-layered and transparent options for integration into existing building and process control systems allow enormous flexibility.

Link to the article: New hydrogen sensors available

What is „EX-i“, "IP-52" and "ATEX"?

EX-I (“IP52”, “ATEX”) deals with the possibility of designing devices who even in the event of a fault they cannot generate or release the amount of critical energy into an environment that is known for critical values of high explosive mixtures of gases, liquids or solids (powder).

Some facts to understand explosion protection and intrinsic safety

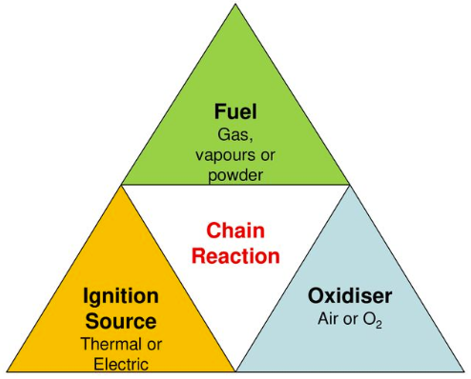

In the end of the 19th century, experts not only did their research in preconditions of an explosion like pressure and mixing ratios of gases, powders and liquids with which they can become explosive, but they also search for strategies and solutions how to protect their own laboratory equipment, production facilities and transport containers. However, their more or less successful experiments indicated the keynote that it is not a specific ignition source that triggers an explosion. They figured out that it must be some kind of generally undefined energy that has to be added in order to overcome the critical ignition point that may finally lead to an explosion.

Intrinsic safe devices

Based on the scientific research in explosion sciences of those early days, today we know that a device is intrinsic safe if it cannot hand over this critical ignition energy in any way as well as any time to an unstable atmospheric scenario.

The "intrinsic safety" of electrical equipment and machines is described in the catalog of measures for modern explosion protection according to IP 52. For this, the operating voltage must be below 24 volts and the current consumption below 100mA.

Why does a sensor that warns of hydrogen sometimes have to be intrinsic save?

In the vicinity of the batteries, hydrogen is produced by the charging process and released to the air around the batteries. Since this gas is lighter than normal air, it rises and, depending on the room, collects under shelves, cable harnesses, false ceilings, etc. The SM_H2_LC is therefore placed in such a way that it draws attention to the danger area in good time.

The operating environment is a crucial point:

It is possible that beneath hydrogen a production process also may produce other highly flammable or even explosive gases. Since the SM_H2_LC is a hydrogen sensor, it will not take a look at other gases that may explode, too.

In other operating scenarios, it may be necessary to place a sensor very close to valves, next to hydrogen container.

In both cases, it is remarkably recommended ensuring that the sensor itself does not inadvertently become an ignition source.

SM_H2_LC can meet the explosion protection according to IP52 and EX-i

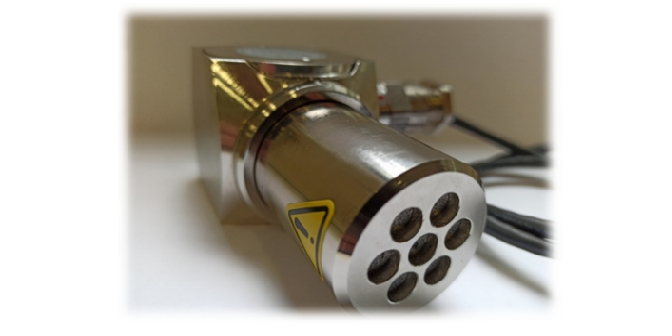

On request, the SM_H2_LC can also be supplied in a specially encapsulated housing, thus fulfilling all the requirements that are necessary for operation in potentially explosive operating environments:

A membrane developed and designed to protect the sensor head with its current-carrying elements from harmful and otherwise explosive substances. Only hydrogen will find a way to the sensor head.

The electronic components are sealed to prevent electrical sparks during a switching operation.

If desired by a customer, the overall alarm behavior can be adjusted so that it detect much lower hydrogen concentrations than the standard sensor setup.

Alternative sensor heads can be used to detect gases that may occur within industrial production processes. Since the sensor can be connected within a daisy chain, different sensors can be connected to a holistic warning and system.