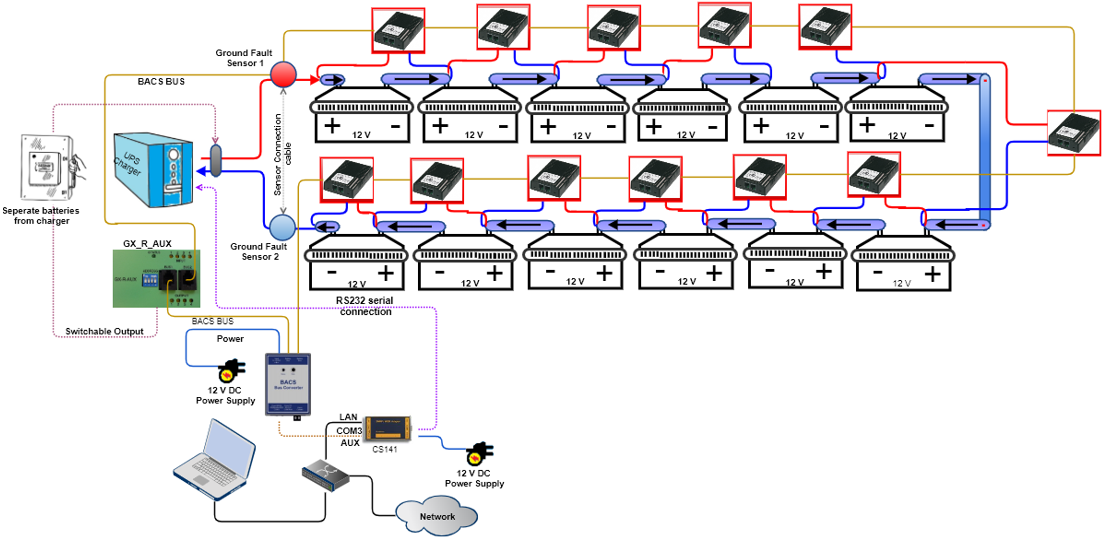

Combined current sensor for BACS and SENSORMANAGER:

Live parts in and on electrical appliances are usually secured so that a user cannot be exposed to them – it is dangerous whenever part or all of the electrical installation does not comply with safety regulations:

Touching not secured live parts of the current conducting elements is dangerous: current will flow directly through the body to the ground and may lead into a fatal electric shock.

The fatality of the electrical shock is depending on many factors, because the current flow takes the path of least resistance. If the heart is involved, it quickly becomes very dangerous to the life - 80 milliamperes can be a deadly current if it lasts longer than the duration of a heartbeat (about 0.8 seconds). But even at lower currents can become problematic:

In the 15 - 20 milliamps the muscles tense up, a region enclosed object cannot be easily released.

From 30 milliamps the respiratory muscles are already affected.

UPS systems provide a particular challenge

UPS systems are in principle components of the electricity grid and connect the ground wire of the upstream system to the protective conductor for downstream systems. Larger systems have a separate fuse for fault current. As long as this is a closed unit, it can be assumed that in a fault current likely to respond to the UPS and strikes depending on equipment or triggering a fuse.

Large systems with external batteries

Larger battery management systems provide a challenge even with a technically trained staff. The more complex the system, the more quickly it can lead to unintended problems one such problem is battery ground fault. This is a problem that may arise, regardless of a UPS, if it is not monitored accordingly. To counter this risk, we have a design a monitor designed to warn the user of battery ground faults - BACS Ground Fault Detector

The BACS Ground Fault Detector determines a current difference between the positive and negative DC connections. When it measures a differential current, it is an indication of a dc ground fault.

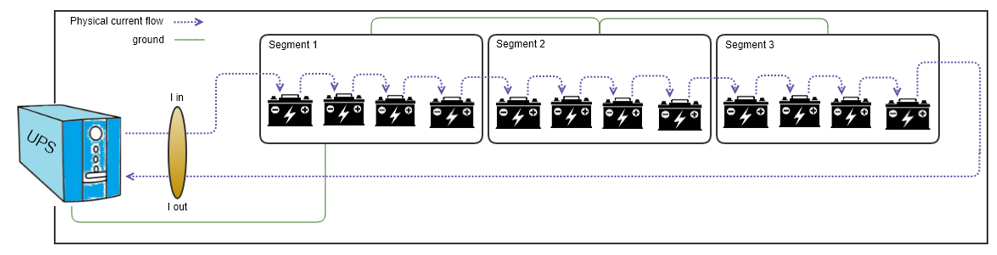

How it works:

The BACS system will analyze the difference between positive and negative current connections. Using Kirchhoff’s current laws in a normal system, the difference between the positive and negative current should be zero. If a battery does ground fault a current difference will be present between the positive and negative sensors.

BACS will inform the user and the user will take the appropriate action.

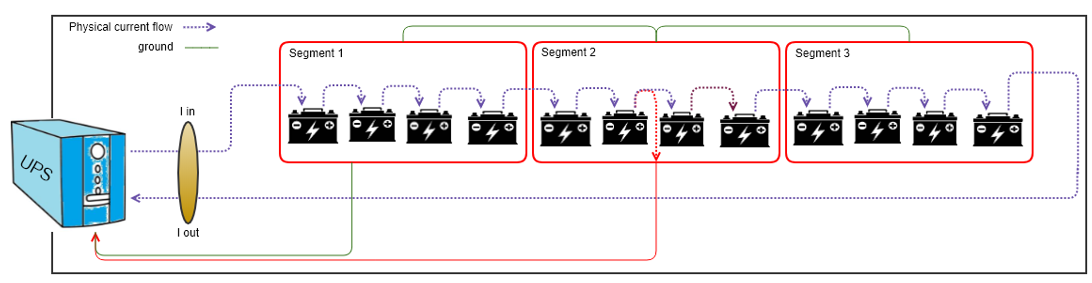

When segment 2 has a ground fault, the result is the following current flow image:

This results in two different currents:

A current via the regular power connections

A current via the ground wire back to UPS.

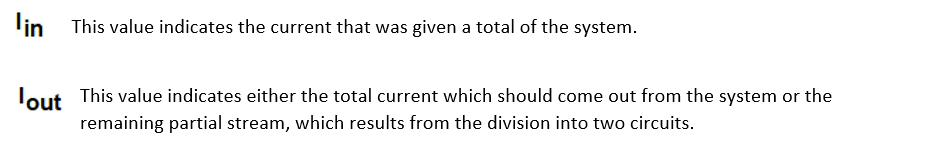

Since power is divided according to the Kirchhoff's current laws, you can see this in the direct comparison:

In this example we are assuming a contact problem, which can happen quickly when installing batteries: A damaged housing allows a current contact between the battery cabinet or rack and the battery - and leads into an current earth fault.

DC ground faults can result in the following:

Over-heating

Auto shut down of power

Equipment fails to work

Damage of equipment

Burning and more serious result

The BACS Ground Fault Detection offers a preventative protection measure for technicians since the corresponding problem can be detected in advance. With some UPS and rectifier systems, ground fault detection is not available at all. However, if this function is available on a UPS or a rectifier, measurements are often limited to discharging battery system:

The current levels are higher during discharge, which can be used to detect an earth fault.

This behavior in particular can damage the batteries and the surrounding systems and lead to failure.

Depending on how large the consumer is, the performance and life of the affected batteries will decrease. In this case, you would be able to provide the Ground Fault Detector to diagnose problems in a controlled mode valuable additional information about the general state of the plant. General differences show up immediately to find the battery that has faulted to the ground. Further analysis of the individual battery data provides an accurate picture of:

Impact on the overall performance

Batteries directly and indirectly affected

The impact of the additional stress on the general failure rate