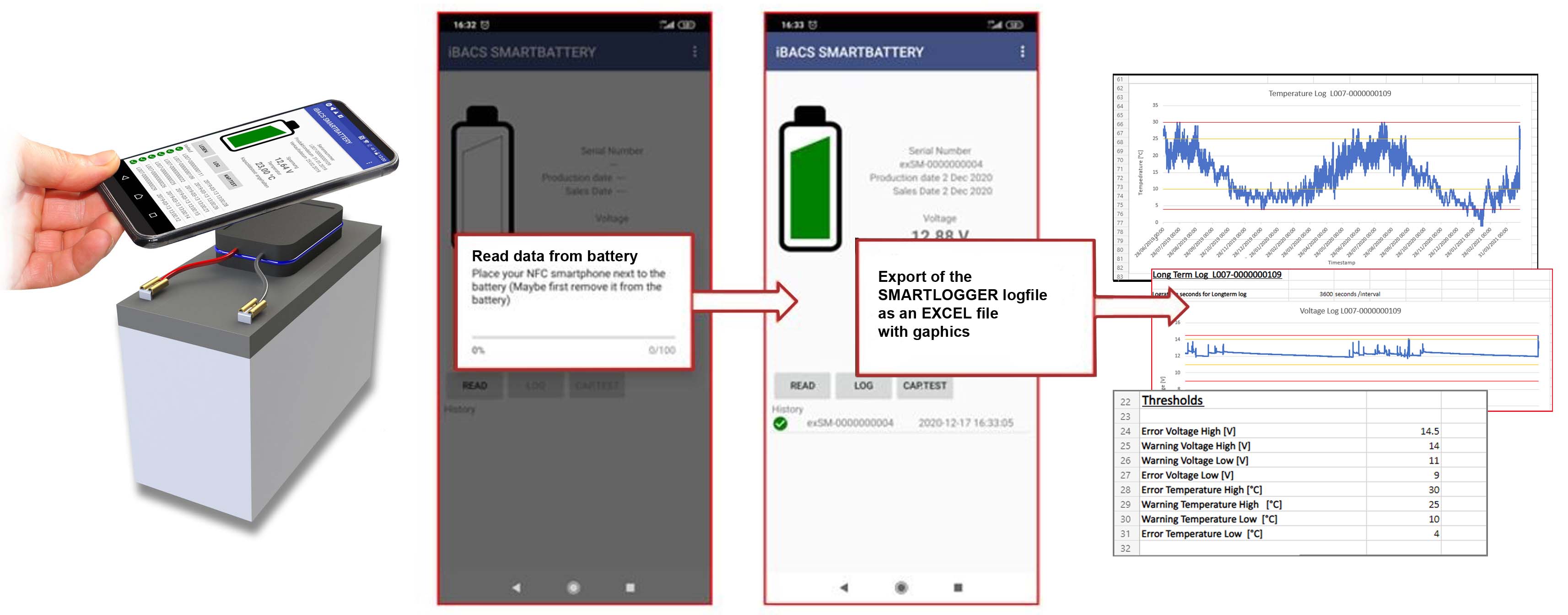

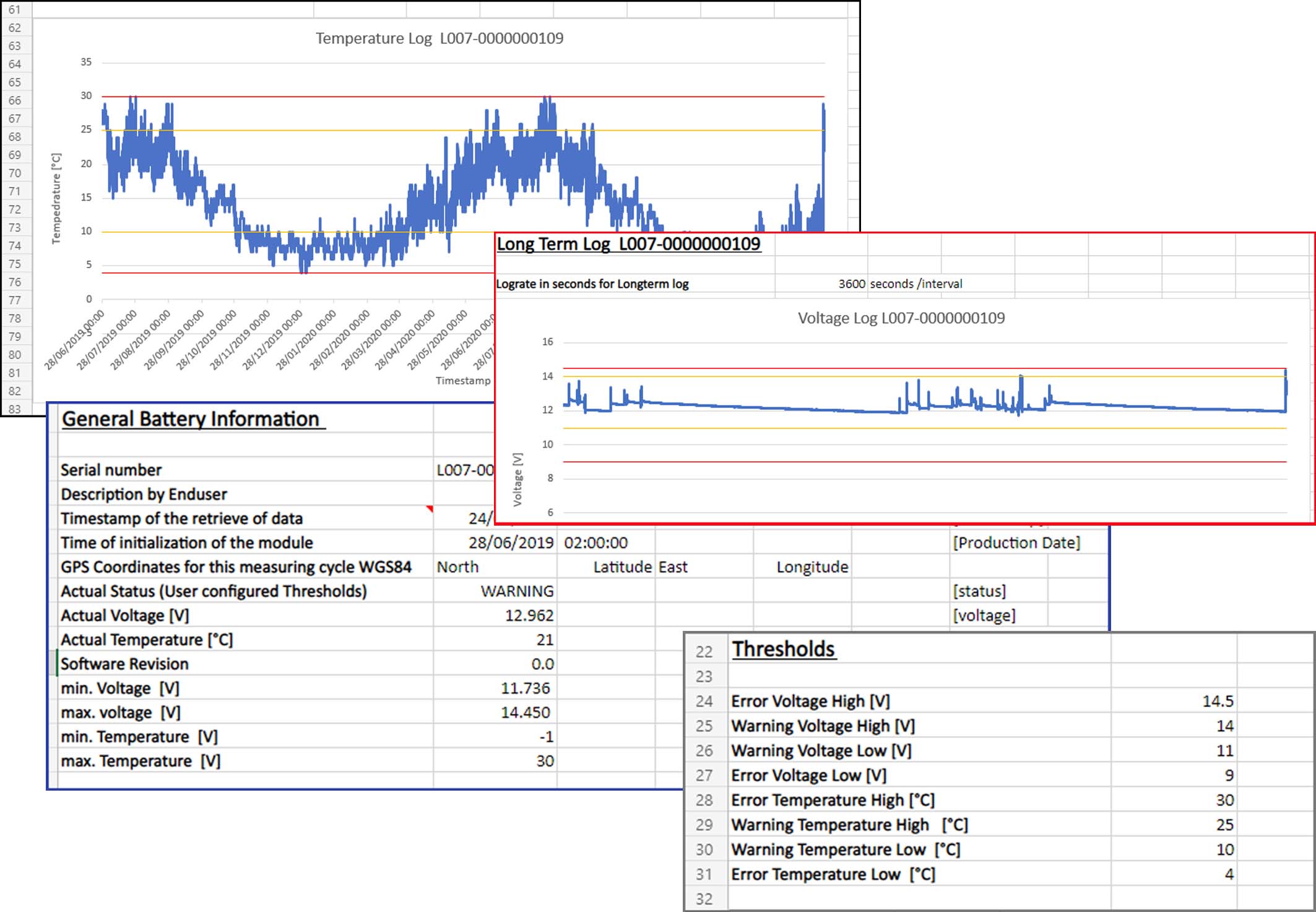

No. 1: Freely definable threshold values for voltage and temperature

The firmware of the SMARTLOGGER in conjunction with the new APP has been expanded to include the option of defining individual threshold values for a battery.

Usage Example:

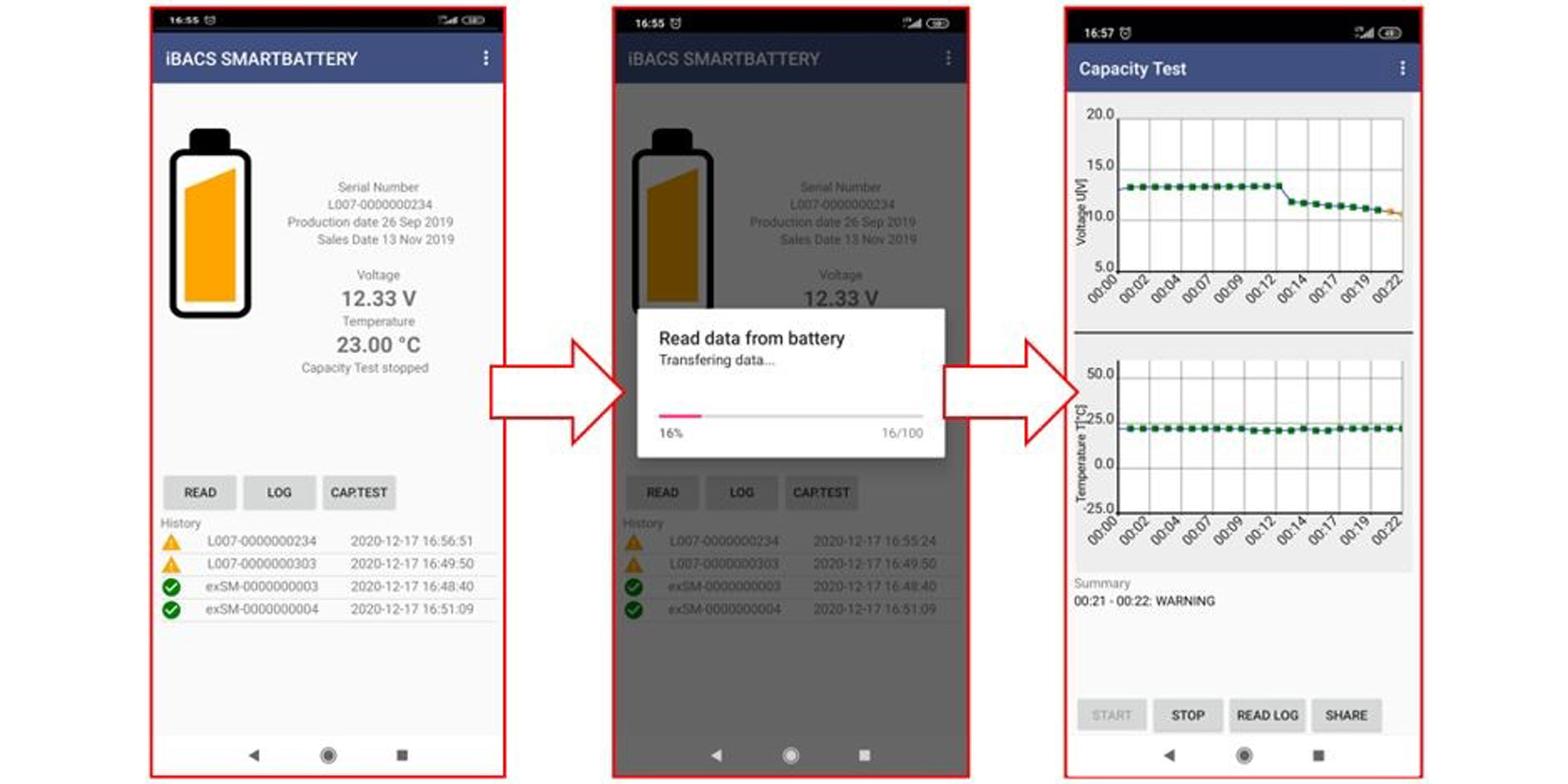

An enormous amount of effort is often put into testing or otherwise measuring the capacity of the batteries. Sometimes even a load generator has to be connected to simulate the “standard” load which in the process actually consumes the current instead of the actual load; we’ve also seen the use of a transfer switch which switches the load via a 2nd UPS for the duration of the test. Service technicians must also record the measured values of the individual batteries as quickly as possible on-site during the discharge test for later evaluation - precisely this requirement is personnel-intensive, and it can be difficult to justify from a costs perspective.

A UPS system can easily have 200 or more batteries - the reliable collection of all data within the necessarily short time window is often not only an error-prone and difficult to perform process, but also a costly one due to the high demand for trained personnel - and in the end there are often only vague answers to important core questions such as:

- How long can the batteries supply the terminals with this load?

- Were there any batteries that were exhausted / failed earlier during the discharge?

The effort traditionally required for a capacity test is enormous - and usually delivers questionable results due to the lack of a possibility to measure IN REAL TIME.