Differential Current Input:

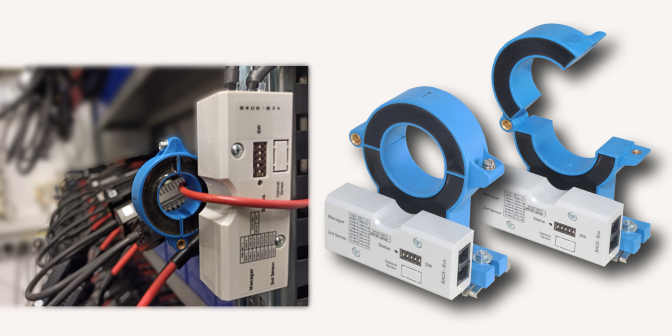

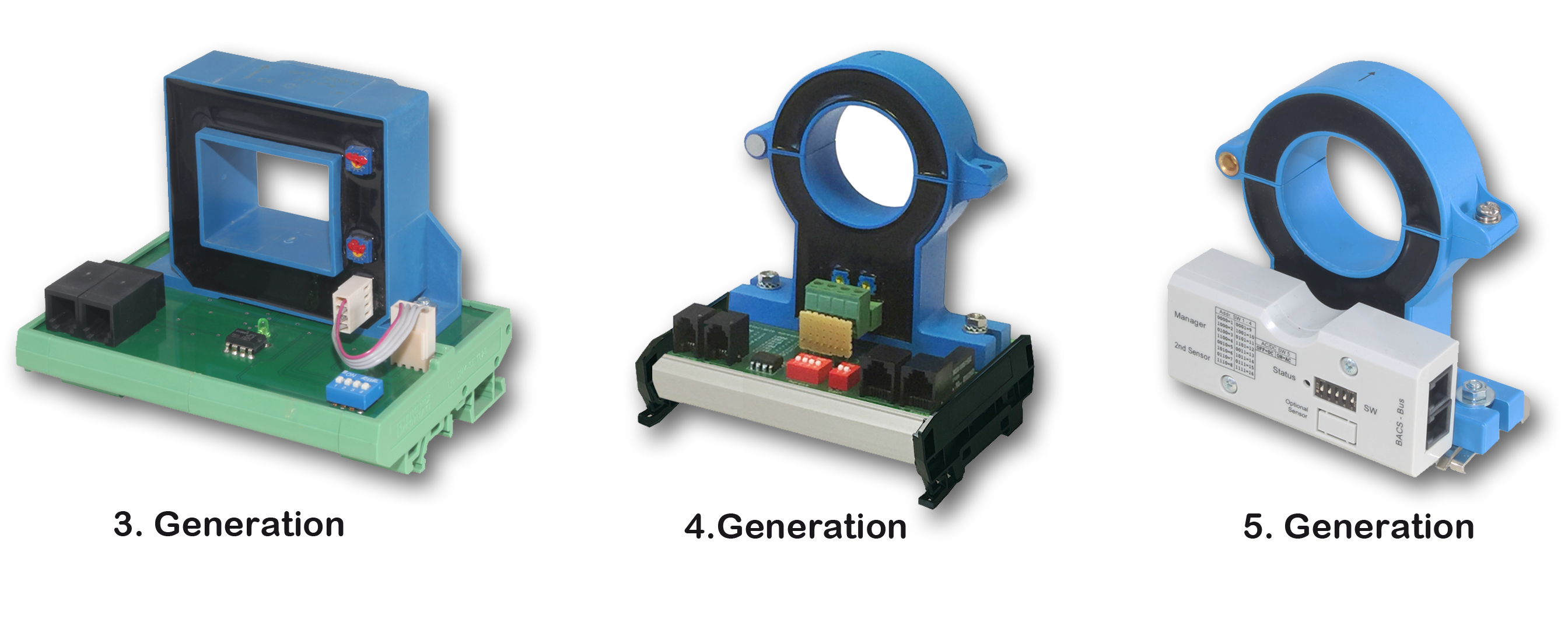

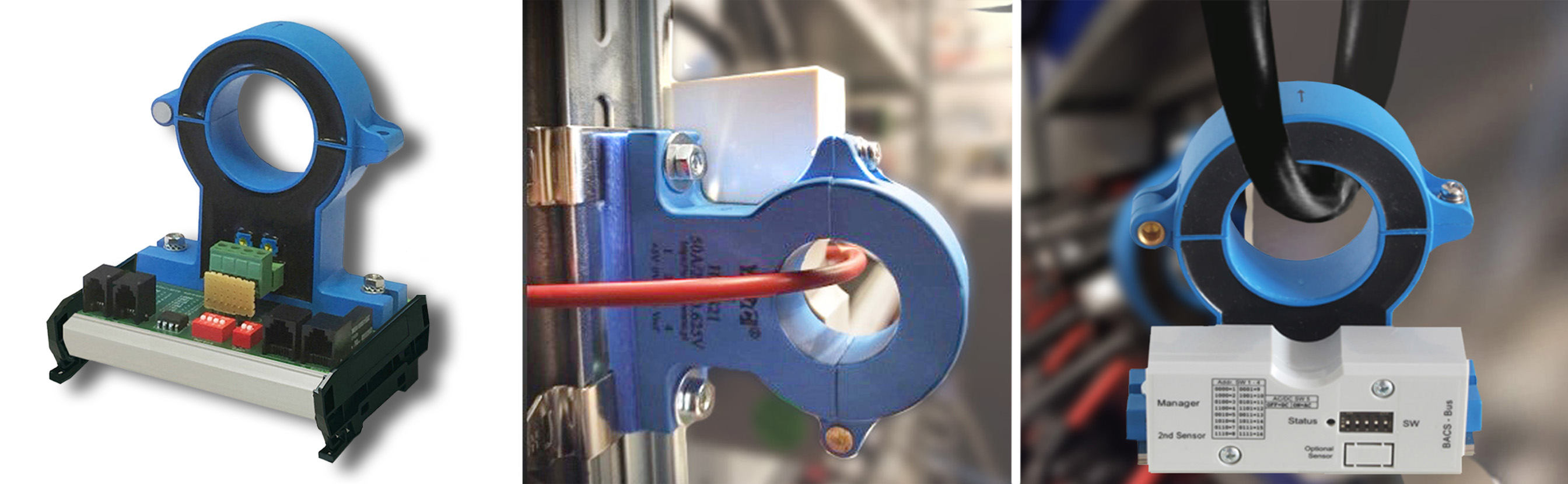

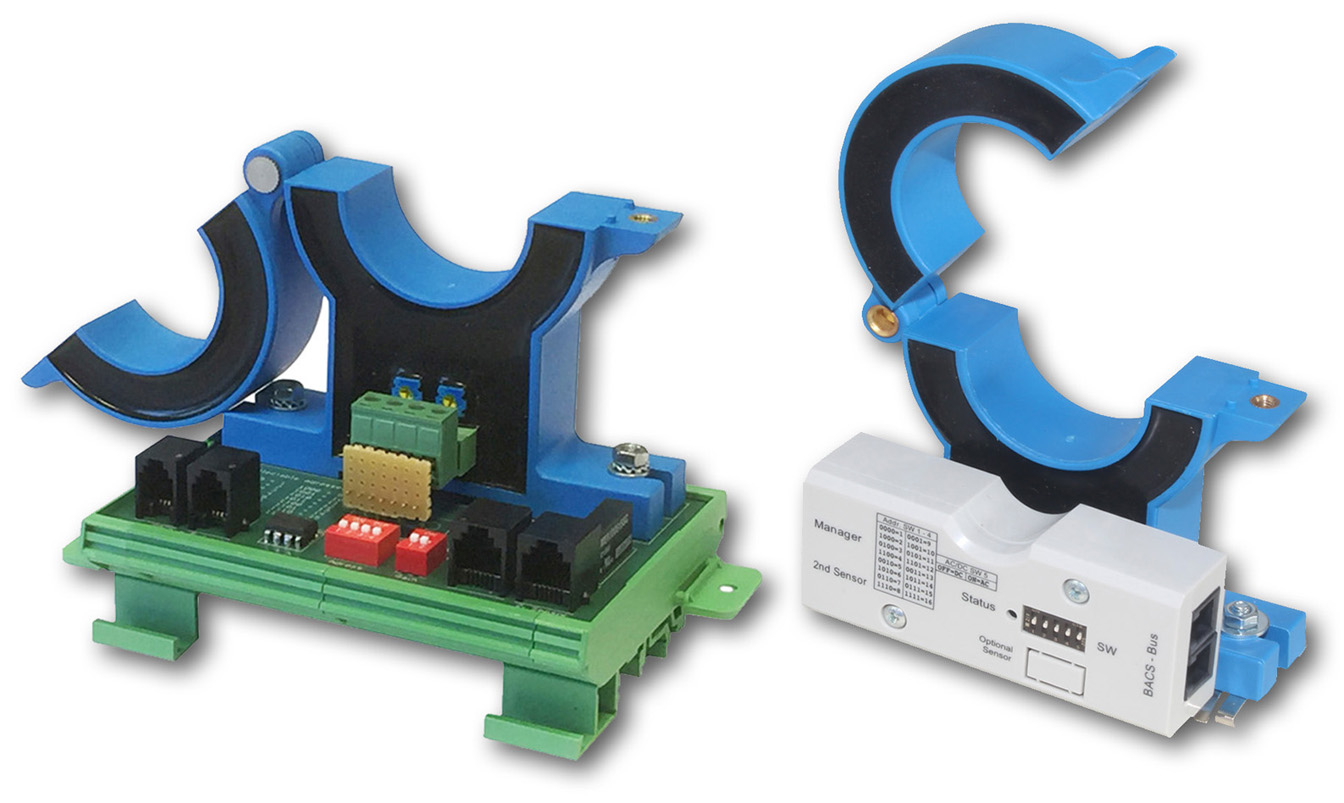

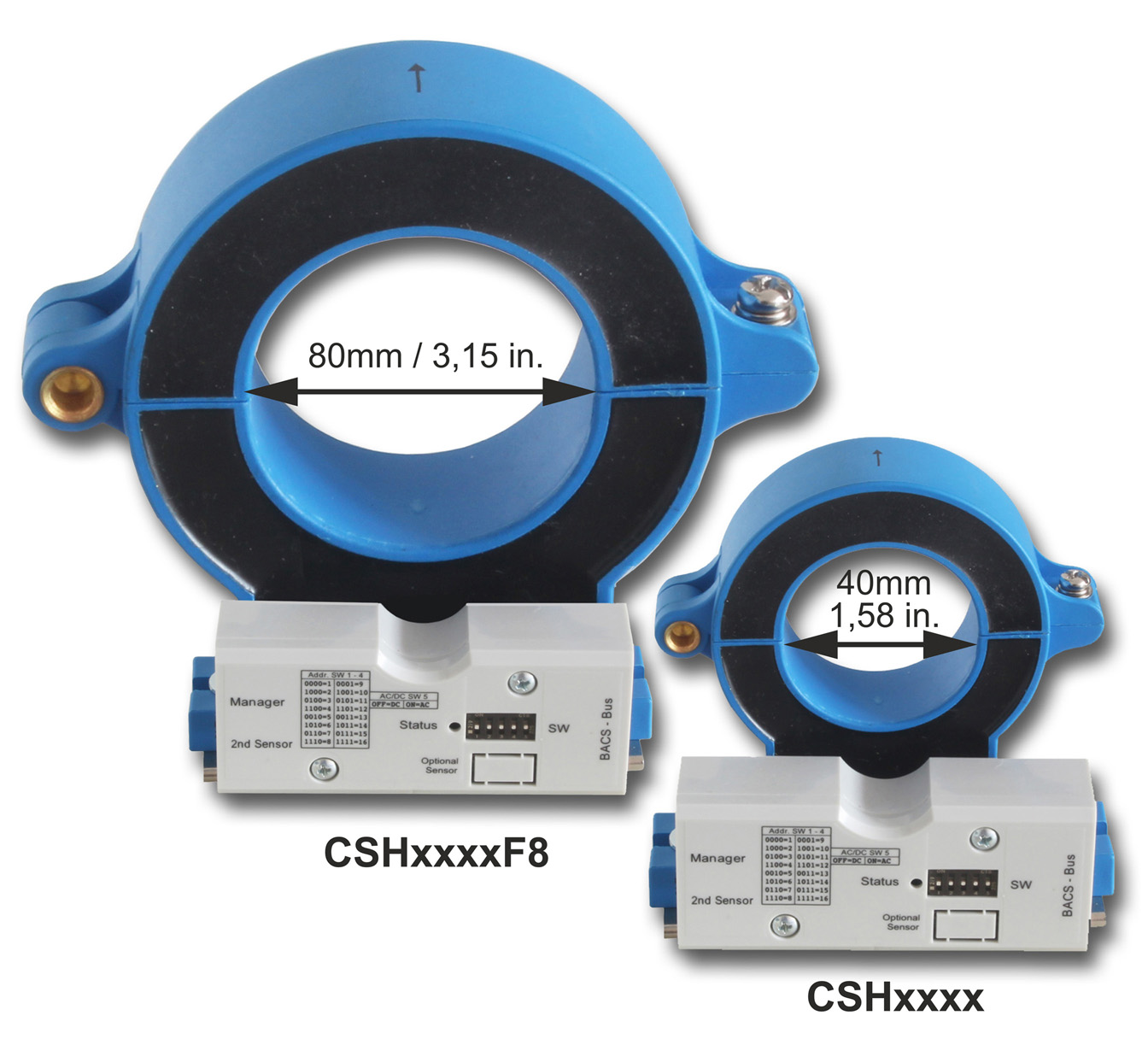

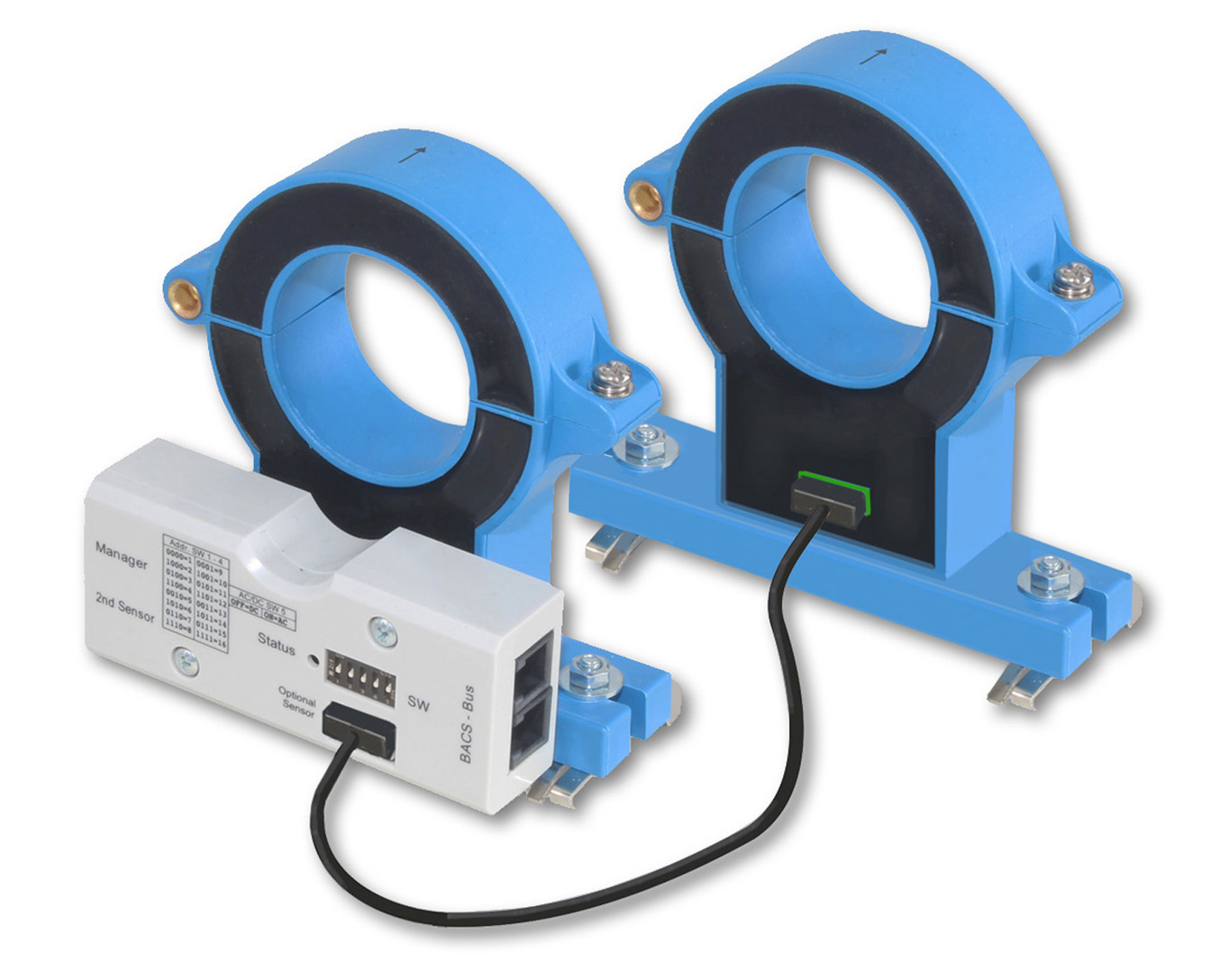

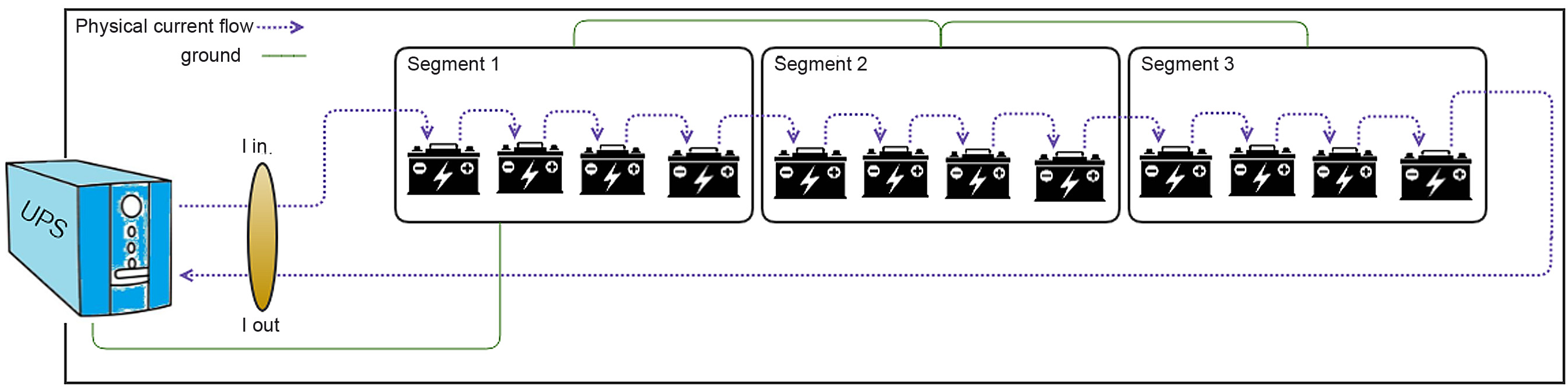

All sensors of the 5th Generation have the possibility to connect the differential current sensor CSHxxxxD in order to detect possible leakages between DC input and DC output.

Residual currents ought by all means be avoided in DC equipment as they can be potentially dangerous – these currents move along a non-linear path, and could cause electrocution if touched. The chance of a fatal electric shock depends on numerous factors, but this problem should be recognized and corrected to prevent injury and personal damage.

Generally live parts of electrical appliances are protected with a personal protection / residual current circuit breaker, but this is not the case with UPS systems! Depending on the specific system, there may be no residual current circuit breaker in use, so that a "leakage" can quickly lead to personal injury. The usual "workarounds" by means of an insulated battery pack etc. provide safety, but because of the potential danger of a leakage current this can lead not only to personal injury, but also to property damage - it is paramount to know immediately if and when such a condition exists. Leakage currents are harmful to the batteries and endanger the UPS technology, and can lead to a fire. For this reason, the use of residual current sensors is required in many tenders in the USA and by the US authority NERC.