SMARTBATTERY – iBACS – SMARTLOGGER

“Basic” as they are, batteries have proven to be among the most critical devices in modern IT systems. Numerous optimizations within battery chemistry now allow for higher and higher energy densities, but such rapid advances often take place according to the inherent limitations of modern technology. The following applies to batteries: the higher the energy density per battery, the lower the permissible tolerances with respect to status fluctuations during operation!

Malfunctions always have consequences, but depending on the battery chemistry used, these consequences might be more or less severe. Acid/lead-based batteries, which can produce hydrogen during charge/discharge cycles, are still comparatively "harmless" in the event of a fault compared to modern battery chemistries such as lithium.

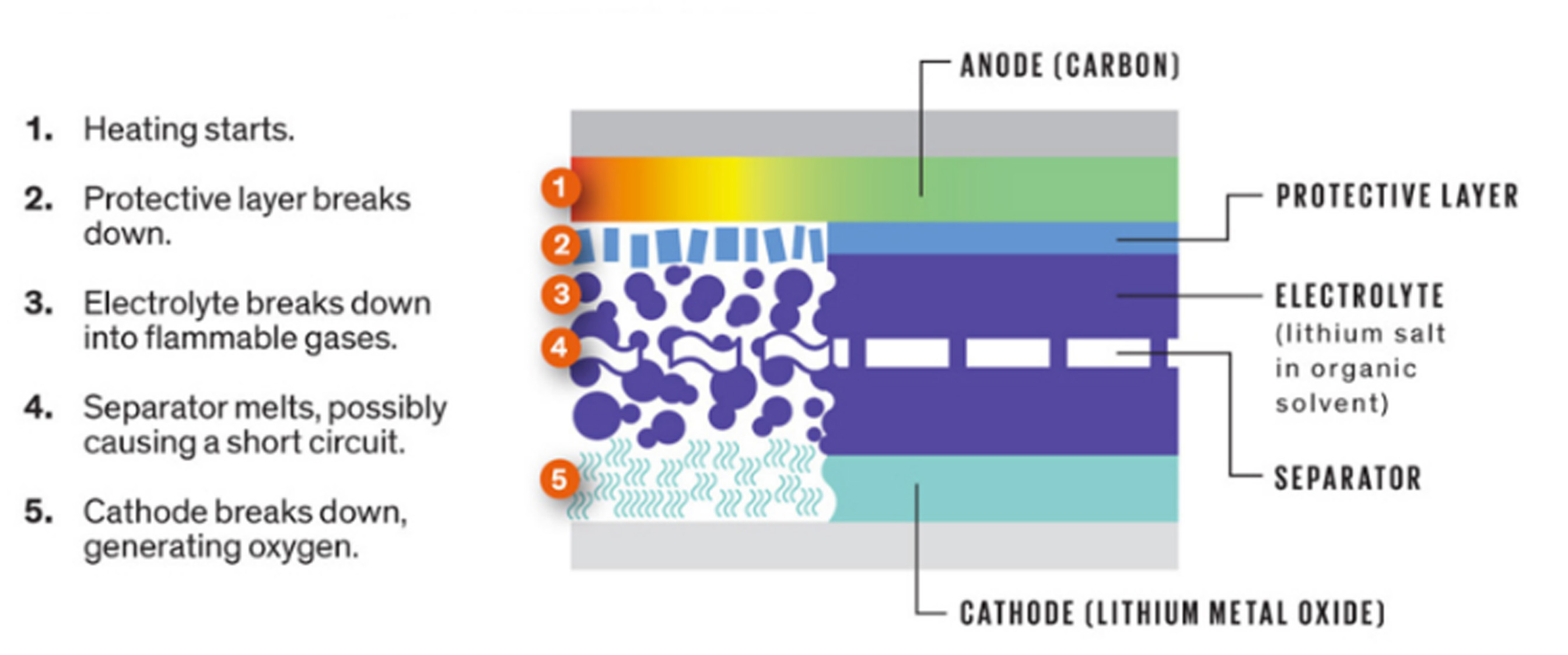

In lithium batteries, it is not the gas that is the problem when electrolyte is lost, but the internal thermal reaction in the case of short circuits. The relatively low temperature above which thermal runaway can no longer be stopped within lithium cells is critical: studies show that the thermal runaway temperature for common battery materials (lithium cobalt oxide cathode and lithium hexafluorophosphate anode) already starts at 67°C (152 °F). Such temperatures are reached quickly; even in normal operation without faults this can happen. With lead-based batteries, where BACS and SMARTLOGGER are mainly used, this is much less critical, but even with such chemistries care should nontheless be taken to ensure that any applicable production, storage and transport conditions are met before a battery is shipped to the customer. This “cradle to grave” style of monitoring is in fact required by EU regulation from 2026 - SMARTLOGGER and SMARTBATTERY offer a solution for these new requirements for the battery industry.

New Requirements for the Battery Industry

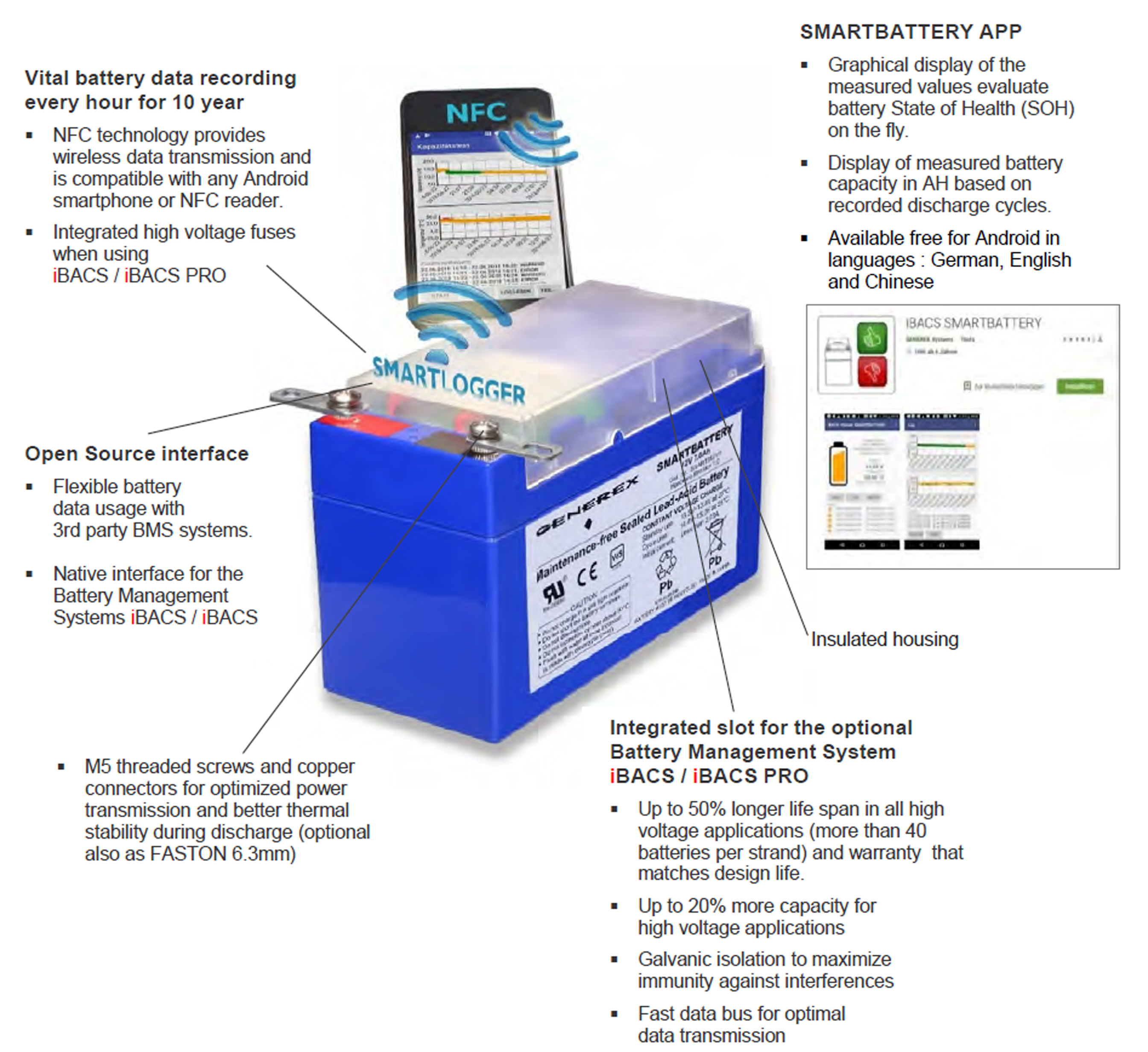

The SMARTLOGGER is in fact a part of the broader SMARTBATTERY concept, and is factory installed any battery sporting the SMARTBATTERY solution. GENEREX licenses this patented technology for battery manufacturers and battery importers – it is available for all lead and lithium based batteries and complies with the new EU regulations scheduled to come into effect in 2026.

(Hint: For more information, have a look at our article “EU Regulation for Batteries “ from this year’s Newsletter)

Indeed, the SMARTBATTERY technology is already activated within the first hours of production within the factory, and recorded data is written into a specially protected “tamper free”, un-erasable memory. Thus, the vital functions (voltage, temperature) of a battery are already recorded during the production process, making the entire production, delivery process, storage and transport conditions transparent, before and after-sale.

This data, and all subsequently recorded data, remain available for the entire service life of the battery. The use of the SMARTBATTERY enables the battery manufacturer to issue increased operating guarantees and fail-safes because quality and operational condition is constantly monitored and documented. A SMARTBATTERY is demonstrably better than any other battery without such technology - and therefore also of a higher quality and safety standard!

Since the SMARTBATTERY by design cannot be reset or tampered with, the measurement data is an incorruptible witness to the use and treatment of the battery and is therefore invaluable in terms of warranty disputes.

The SMARTBATTERY is compatible with any currently available battery chemistry and provides the manufacturer with otherwise missing insight about production, storage and transport. Seamless proof can be provided that a battery could not have suffered hidden damage due to improper handling during production, transport or storage, and for 10 years each battery records further mistreatment if and when it occurs. In addition, because each battery contains a unique and tamper-proof serial number, battery suppliers can collect supply chain information to prove compliance with EU and national safety regulations during transportation, installation, and recycling. At the end of its use life, the stored data can be used to prove that the battery was disposed of properly.

=> The EU directive for the battery industry valid 2026 is already fulfilled today, with the SMARTBATTERY!

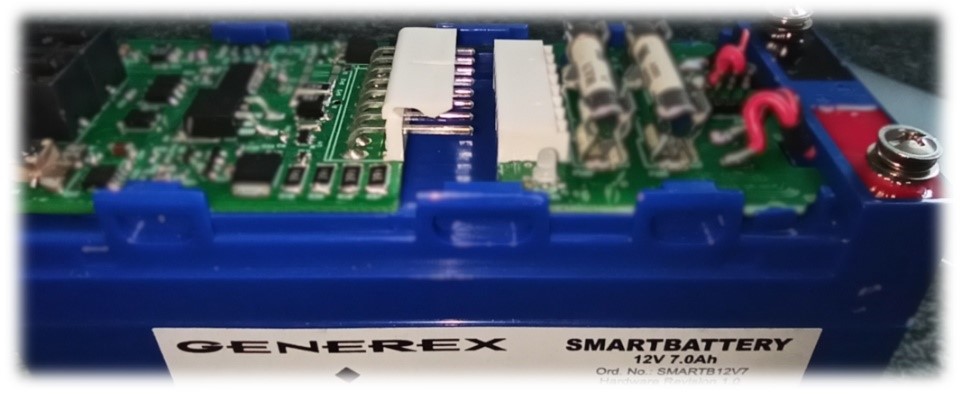

Optionally, a SMARTBATTERY provides an additional slot for expansion cards to integrate e.g. an "iBACS" system ("Integrated BACS") or other similar such BMS solutions from 3rd party suppliers.

Picture: SMARTBATTERY (in blue) with SMARTLOGGER integrated, high voltage fuses and interface to the "iBACS" - BACS module for optional insertion into the SMARTBATTERY.

If the interface of the SMARTBATTERY is equipped with "iBACS", the data collection and archiving continues in parallel, but additionally serves the "iBACS" module with data. This redundant data collection and archiving is unique and makes SMARTBATTERY/BACS the most flexible system on the market at the lowest operational cost. GENEREX offers the patented SMARTLOGGER technology to all BMS vendors to allow battery manufacturers to use not only GENEREX products for their SMARTBATTERY models.

The new requirements for the battery industry also result in new opportunities for the battery service technician!

New Frontiers for the Battery Service Technician

With the SMARTBATTERY and SMARTLOGGER, GENEREX has introduced a flexible and modular battery monitoring solution that allows technicians to track and check the real-time battery condition on site during installation.

Picture: SMARTLOGGER with FASTON 6.3mm (also available with Ringcableshoes in different sizes and length) and SMARTLOGGER with Crococlamps for Battery Service Engineers

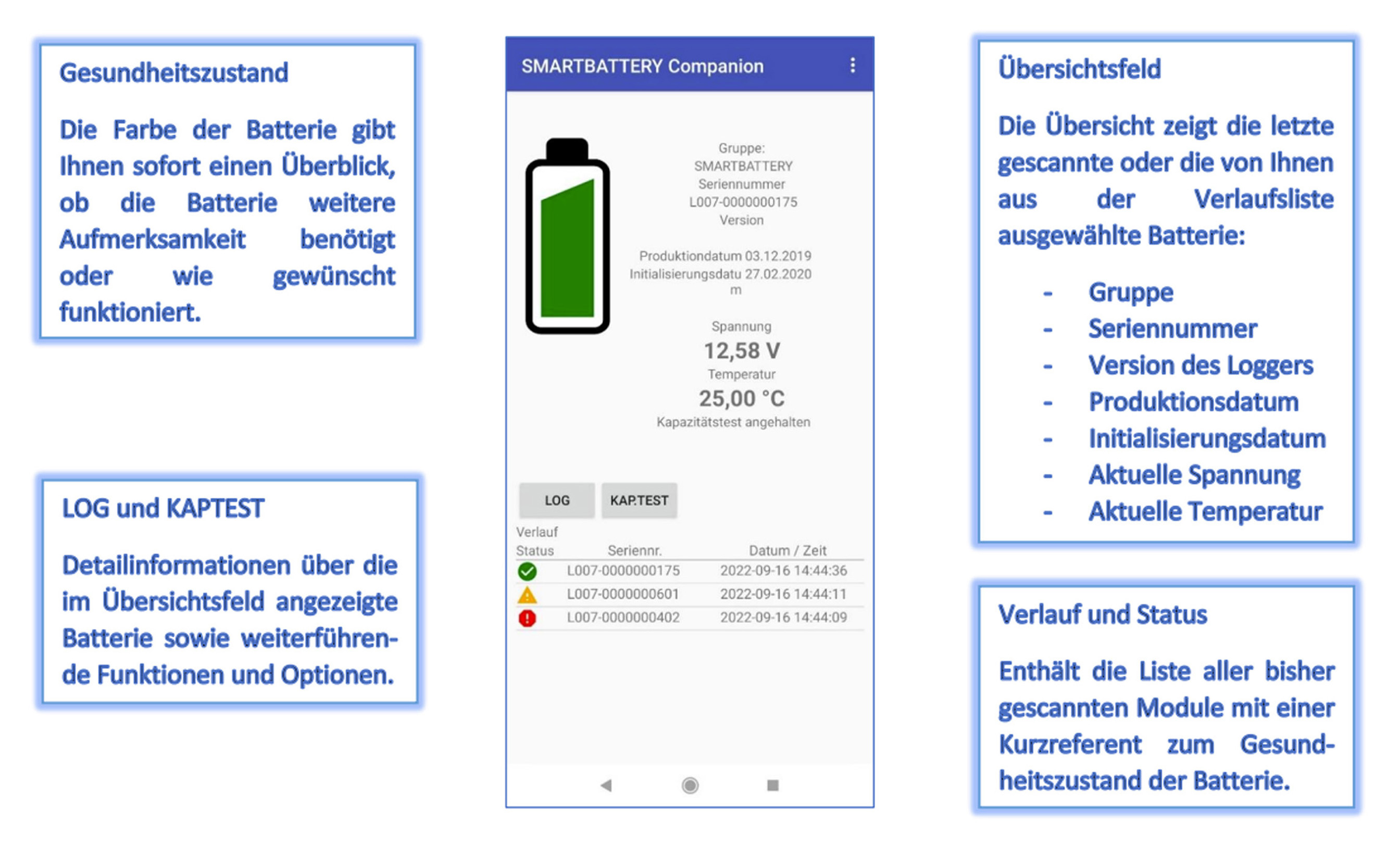

The SMARTBATTERY and SMARTLOGGER allow the technician to directly measure the capacity of batteries without complex measurement setups. Any battery equipped with SMARTBATTERY technology can be read via the SMARTBATTERY Companion APP using NFC within 1-2 seconds.

The iBACS/SMARTBATTERY/SMARTLOGGER APP immediately provides all important information about a given battery’s operating and health status. For this, the batteries to be monitored must either already be "SMART", i.e. already have the SMARTBATTERY technology installed - or be retrofitted with a SMARTLOGGER.

Difference to SMARTBATTERY:

The SMARTLOGGER is identical in function to the SMARTBATTERY, but the SMARTLOGGER is an external module intended for retrofit AND/OR for the battery service technician as a "tool" for battery testing.

Exceptions:

- The SMARTLOGGER lacks any sort of „slot“ for upgrade/expansion through use of the iBACS card.

- Unlike the SMARTBATTERY, the SMARTLOGGER can be "reset" by the technician, so it is not "married" to the battery for life, but can be used on another battery at any time. This makes the SMARTLOGGER a "tool" and is ideal for battery capacity tests or for temporary monitoring of installations. For this type of application, we offer the SMARTLOGGER with "crocodile clips" and with ring terminals, depending on how long the SMARTLOGGER is to be connected to the battery.

This way, a service technician can measure and document battery systems on site with less effort. After all data has been "collected", the SMARTLOGGER can then be reset to a „fresh“ state via APP command, and thus be made ready for use at the next customer.

The SMARTBATTERY Companion APP Version 2.0 is also new.

SMARTBATTERY Companion App 2.0

New Functions for the SMARTBATTERY, iBACS and SMARTLOGGER

New Functions for the SMARTBATTERY, iBACS and SMARTLOGGER

New features, more power, more convenience and more customer needs met: The new iBACS SMARTBATTERY and SMARTLOGGER Companion APP version 2.0 is here!

Available for free on GOOGLE PLAYSTORE!

Reliable data, measured whenever!

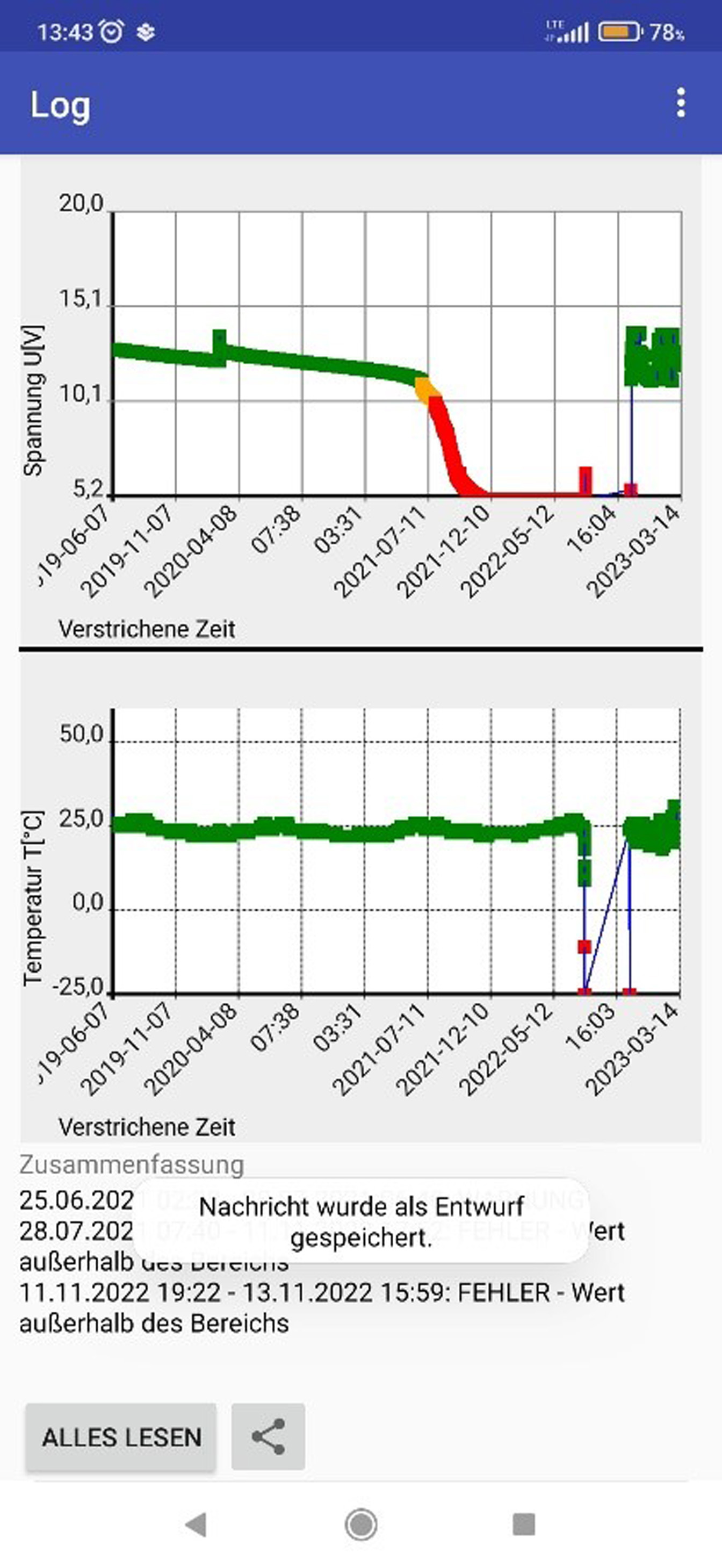

As the SMART technology functions as a component of the battery itself, the SMARTLOGGER continuously stores operating data from the respective battery and, if required, immediately provides all the necessary data to make a statement or decision about the need for action. The storage capacity is at least 10 years.

Real-time battery data and records are transferred directly to any Android phone or NFC reader via the SMARTBATTERY Companion App and an NFC interface.

The SMARTBATTERY technology offers significant cost advantages over a traditional BMS, with the limitation that the data must be collected by the technician via NFC and are not available on the network without using the interface.

Capacity Test

With the capacity test, one can calculate the expected capacity which might be extracted during a discharge.

Functionality of the Capacity Test:

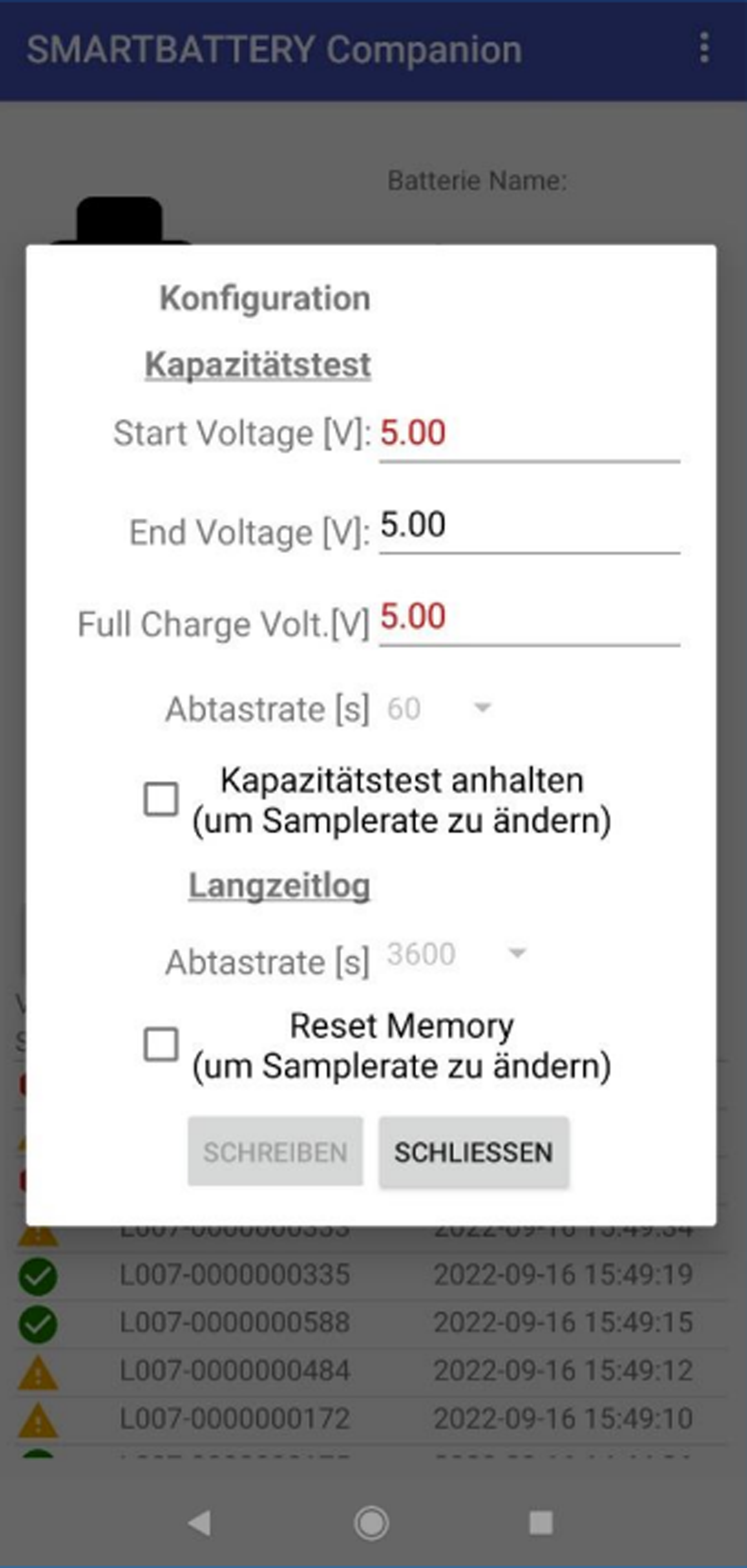

Simply connect the SMARTLOGGER to the battery and click "START" on capacity test within the APP. The SMARTLOGGER or SMARTBATTERY increases the recording frequency and the discharge can begin. If necessary, the limits for the capacity test can be configured individually.

Since the app already comes with complete graphical offline monitoring, values of particular concern can be evaluated directly on site if required.

For further analysis, the battery data can be exported and sent via standard technologies such as mail or messaging services.

Battery data can be easily exported for use in Status Reports, etc

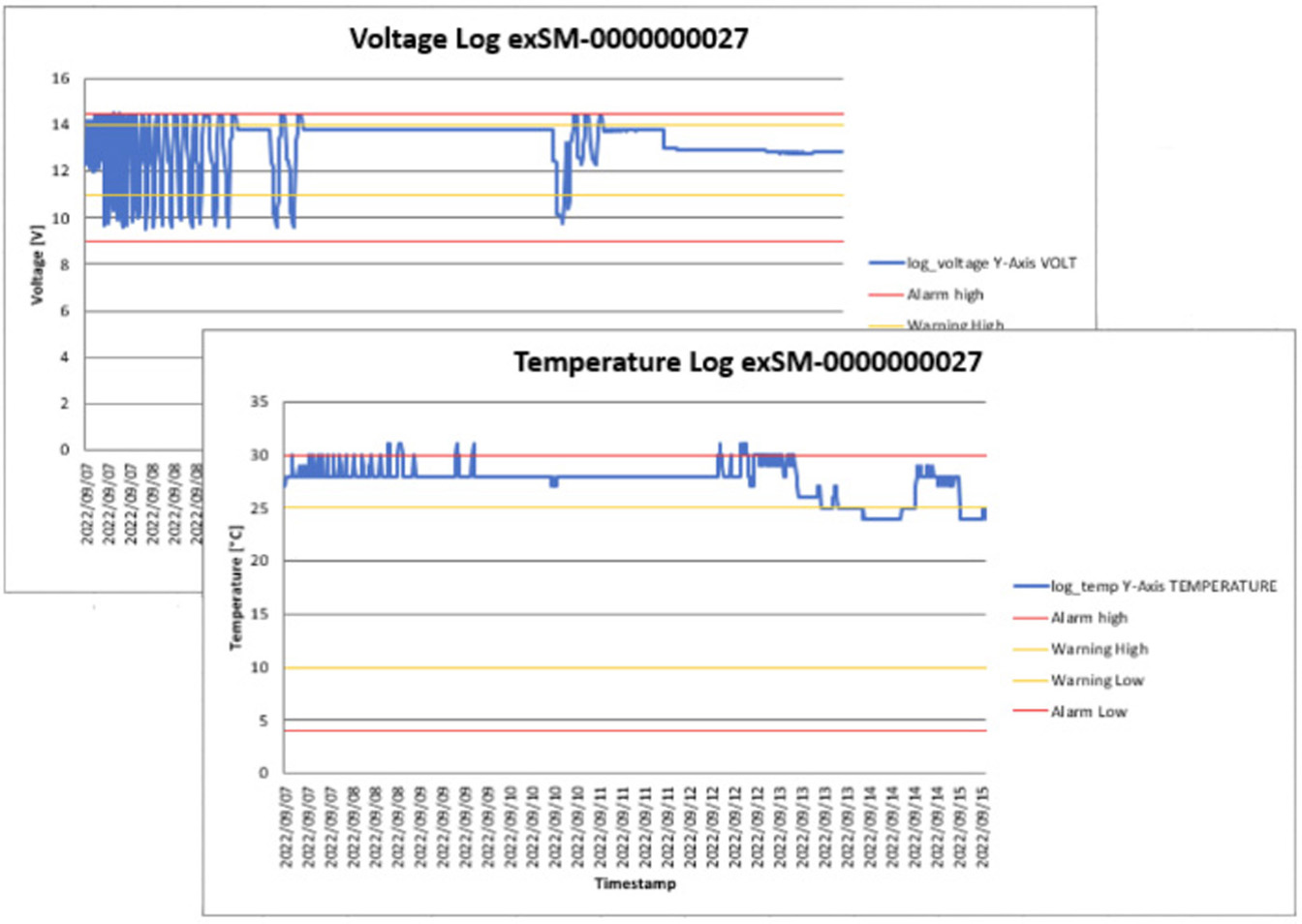

The data format of the APP can be exported by means of SMARTBATTERY Exporter - a freely available Windows program from the GENEREX website (SMARTBATTERY | Generex) - into an EXCEL format file; the file will automatically display a graphical representation of the recorded data upon exportation to EXCEL – you can find an example in the image to the right. The voltage and temperature curve with set limit values is displayed in the EXCEL graphic, easily recognizable are deep discharges or other limit value violations and can be used in a report.

Black Box - With SMARTBATTERY, you record the path of a battery ex works "from the cradle to the grave " and meet the new EU directives for 2026 in the traceability of problematic materials.

What else have we improved with

SMARTBATTERY Companion APP 2.0?

- Name Change to "SMARTBATTERY Companion": the name of the APP has been changed - now you can find the APP in the GOOGLE Playstore under the search terms "iBACS", "SMARTBATTERY", "SMARTLOGGER".

- BATTERY GROUPS: The function "ADD GROUP" creates a distinct battery group for each given customer in which all measurement results can be collected via drag'n'drop within the battery overview interface. This allows the Android phone to manage even larger battery systems for different customers.

- "LOG" Function is able to process very large data packets >200k/>10 years.

- A new Windows tool called the SMARTBATTERY EXPORTER – available for free via GENEREX website – converts all data to a Microsoft EXCEL compatible format and automatically generates graphs that can be used directly in a service report.

- LOGRATE setting - depending on the application, the LOGRATE can now be set individually, e.g. to set a faster data measurement or a slower interval to extend the capacity of the LOGFILE to more than 10 years.

Back to

Next Article