SMARTBATTERY / SMARTLOGGER Companion App 3.0

GENEREX ist es im Jahr 2024 erneut gelungen ein Patent zu erhalten. Unter der EU-Patentnummer 18726032.8 mit dem Titel „Verfahren und „Vorrichtung zum Batteriemanagement sowie Batterie mit integrierter Vorrichtung zum Batteriemanagement“ hat GENEREX das alleinige Recht Produkte mit dieser Funktion innerhalb der EU herzustellen, zu vertreiben bzw. zu lizensieren.

Die in diesem Patent beschriebene Funktion verwendet der „SMARTLOGGER“ bzw. die in der Batterie integrierte Version, die dann „SMARTBATTERY“ genannt wird. Es ist aktuell das einzige System auf dem EU-Markt, welches mittels NFC (Near Field Communication) berührungsfrei Batteriedaten lebenslang speichern kann und die Regeln für einen „EU Battery Passport“ erfüllt.

Für die Batterieindustrie und Batterieanwender steigen mit dem neuen EU-Batterie-Gesetz ab 2024 die Anforderungen

Viele Hersteller waren sich schon länger bewusst, dass eine neue EU-Verordnung für Batterien kommen würde, aber haben es vielerorts verdrängt oder eventuell die Hoffnung gehegt, dass es doch noch gekippt wird. Oberflächlich betrachtet zielt das neue EU-Gesetz hauptsächlich auf die Elektromobilität, deren Batterien meistens auf der Basis von Lithium arbeiten und genau deshalb skeptisch betrachtet werden: Die wahre Herkunft solcher Antriebsbatterien ist mitunter bei Importen nicht immer eindeutig, und der Anwender ist aufgefordert, die von der EU geforderten Informationen zu liefern.

Die neue EU-Batterieverordnung 2024 hat jedoch weitreichende Konsequenzen für alle Anbieter in dieser Branche, nicht nur aus Umweltschutzgründen, sondern auch aus Sicherheitsgründen: Zahlreiche Optimierungen innerhalb der Batteriechemie erlauben inzwischen hohe Energiedichten, allerdings oftmals am Grenzbereich der Technik.

Das mag bei bleibasierenden Akkus, bei denen BACS und SMARTLOGGER hauptsächlich eingesetzt werden, nicht so kritisch sein, da die Energiedichte nicht so hoch ist wie bei Lithium-basierten Batterien. Doch die Vorgaben der Batterieverordnung greifen auch hier verbindlich: Die Anbieter von batteriegestützten Systemen sind ab 2024 verpflichtet, darauf zu achten, dass Produktionsrahmen-, Lagerungs- und Transportbedingungen eingehalten werden, bevor eine Batterie zum Kunden geht. Bis 2026 kommt zudem noch der lückenlose Nachweis bis zur Entsorgung hinzu, um zu verhindern, dass schadhafte oder defekte Batterien „heimlich“ in Umlauf gehen. Diese Überwachung – „von der Wiege bis ins Grab“ - wird insbesondere von der EU-Verordnung ab 2024 eingefordert und soll in einem „Batterie Pass“ der elektronisch ausgelesen werden kann bei jeder Batterie, die in der EU in Verkehr gebracht wird, angebracht sein. SMARTLOGGER und SMARTBATTERY bieten bereits jetzt eine Lösung für diese neuen Anforderungen an die Batterieindustrie.

Neue Anforderungen an die Batterieindustrie

Der „SMARTLOGGER“ ist das Herz einer „SMARTBATTERY“ und ab Werk eingebaut. Der SMARTLOGGER ist aber auch als lizensierte und patentierte Technologie für Batteriehersteller und Batterieimporteure mit einer eigenen Batterieserie verfügbar, die genug Platz für den Einbau der Elektronik hat. Er ist für alle Blei-, NiCd und Lithium-basierenden Batterien einsetzbar und erfüllt die neuen EU-Vorschriften.

(Lesen Sie dazu auch unseren Artikel "EU-Verordnung über Batterien" in diesem Newsletter!)

Die SMARTBATTERY-Technologie wird bereits in den ersten Stunden der Produktion ab Werk oder ab Initialisierung beim Kunden aktiviert und schreibt seine Daten in einen speziell geschützten und nicht mehr löschbaren Speicher. Damit werden die Vitalfunktionen (Spannung, Temperatur) einer Batterie bereits während des Produktionsprozesses in konfigurierbaren Intervallen erfasst und macht damit den gesamten Produktions- und Lieferprozess, sowie Lager- und Transportbedingungen vor und nach dem Verkauf transparent. Diese und alle folgenden Daten bleiben für die gesamte Lebensdauer der Batterie verfügbar.

Der Einsatz der SMARTBATTERY ermöglicht es dem Batteriehersteller erhöhte Betriebsgarantien und Ausfallsicherheiten auszusprechen, da die eigene Qualität damit ständig überwacht und dokumentiert wird. Eine SMARTBATTERY ist allein durch die Nachprüfbarkeit der Performance für den Anwender nachweislich besser als jede andere Batterie ohne solche Technik – und damit höherwertig und sicherer!

Die SMARTBATTERY ist mit nahezu jeder aktuellen Batteriechemie kompatibel und verschafft dem Hersteller den ansonsten fehlenden Einblick über Produktion, Lagerung und Transport. Lückenlos kann nachgewiesen werden, dass eine Batterie weder in der Produktion, Transport oder im Lager durch unsachgemäße Behandlung einen versteckten Schaden erlitten hat und dies für einen Zeitraum von bis zu 10 Jahren. Da jede Batterie zudem eine eindeutige und fälschungssichere Seriennummer enthält, können Anbieter von Batterien Informationen über Lieferketten sammeln und somit die Einhaltung von EU- und nationalen Sicherheitsrichtlinien bei Transport, Installation und Recycling belegen. Am Ende der Gebrauchsdauer kann anhand der gespeicherten Daten nachgewiesen werden, dass die Batterie ordnungsgemäß entsorgt wurde.

=> Der „Passport“ einer Batterie ist der SMARTLOGGER

Optional kann eine SMARTBATTERY zusätzlich einen Einbauslot für Erweiterungskarten erhalten um z.B. ein „iBACS“ System ("Integrated BACS") oder anderes BMS von anderen Anbietern zu verwenden und die aufgezeichneten Messdaten übergeben.

Wird die Schnittstelle der SMARTBATTERY mit „iBACS“ ausgestattet, läuft die Datensammlung und Archivierung parallel weiter, bedient aber zusätzlich das „iBACS“-Modul mit Daten.

GENEREX öffnet die patentierte SMARTLOGGER-Technologie für alle BMS-Anbieter, um so den Batteriehersteller die Möglichkeit zu geben, nicht nur GENEREX „iBACS“ für seine SMARTBATTERY-Modelle zu verwenden.

Aus den neuen Anforderungen der EU für die Batterie-Industrie ergeben sich aber auch neue Chancen für den Batterieservice-Techniker!

Neue Chance für den Batterie-Service

Mit dem SMARTLOGGER führt GENEREX eine flexible und modulare Lösung für ein Batterie-Monitoring ein, mit der Techniker nicht nur den allgemeinen Batteriezustand nachverfolgen kann, sondern auch während der Installation vor Ort direkt überprüfen kann, in welchem Zustand sich die Batterie tatsächlich befindet.

Der SMARTLOGGER erlaubt dem Techniker, ohne komplexe Messaufbauten direkt die Kapazität von Batterien zeitgleich zu messen. Jede Batterie, die mit der SMARTBATTERY-Technologie ausgerüstet wurde, kann über die „SMARTBATTERY Companion APP“ per NFC binnen weniger Sekunden ausgelesen werden und wird in einer EXCEL Datei ausgewertet und grafisch aufbereitet.

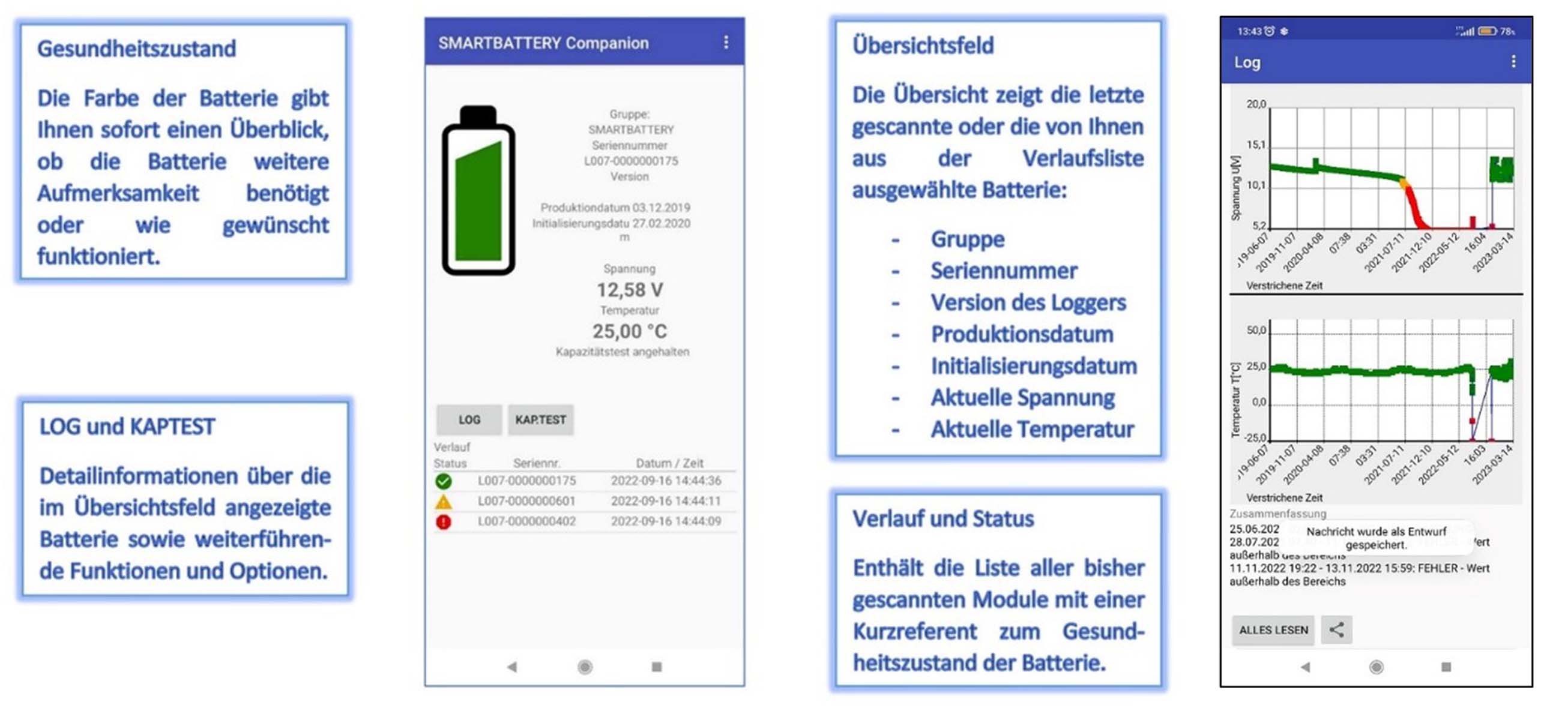

Die SMARTBATTERY COMPANION APP im Google Playstore liefert sofort alle wichtigen Informationen über den Betriebs- und Gesundheitszustand. Dazu müssen die zu überwachenden Batterien entweder bereits „SMART“ sein, also den SMARTLOGGER bereits eingebaut haben – oder mit einem SMARTLOGGER nachgerüstet werden.

Unterschied zur SMARTBATTERY:

Der SMARTLOGGER ist von der Funktion her identisch zur SMARTBATTERY, aber für Nachrüstung gedacht UND/ODER für den Batterieservicetechniker als „Werkzeug“ für Batterietests.

- Der SMARTLOGGER hat keine Schnittstelle für ein iBACS-Modul, um diese dann auf ein BACS-System zu erweitern

- Im Unterschied zur SMARTBATTERY kann der SMARTLOGGER vom Techniker „zurückgesetzt“ werden (nicht die Serialnummer und ID), ist also mit der Erstinbetriebnahme nicht mit der Batterie lebenslang „verheiratet“, sondern kann jederzeit auf einer anderen Batterie wieder eingesetzt werden. Dies macht den SMARTLOGGER zu einem „Werkzeug“ und ist ideal für einen Batterie-Kapazitätstest oder für eine zeitweise Überwachung von Installationen. Hinweis: Das zurücksetzen eines SMARTLOGGERs um diesen für eine erneute Messung auf anderen Batterien zu verwenden ist dem Batterieservicetechniker vorbehalten mit einer speziellen Version der SMARTBATTERY COMPANION APP und kann ausschließlich auf nicht gehärteten Versionen des SMARTLOGGERs angewendet werden. Für diese Art der Anwendung bieten wir den SMARTLOGGER mit „Krokodilklemmen“ – im Gegensatz zu Ringkabelschuhen, die für die dauerhafte Montage verwendet werden und nicht zurücksetzbar sind.

Ein Servicetechniker kann auf diese Weise Batterieanlagen vor Ort mit wesentlich geringerem Aufwand erheblich genauer messen und dokumentieren. Nachdem alle Daten „eingesammelt“ wurden, wird der SMARTLOGGER per APP-Befehl auf den Auslieferungszustand zurückgesetzt und ist bereit für den Einsatz beim nächsten Kunden.

NEW: SMARTBATTERY Companion App 3.0

Auswertung der SMARTBATTERY und SMARTLOGGER

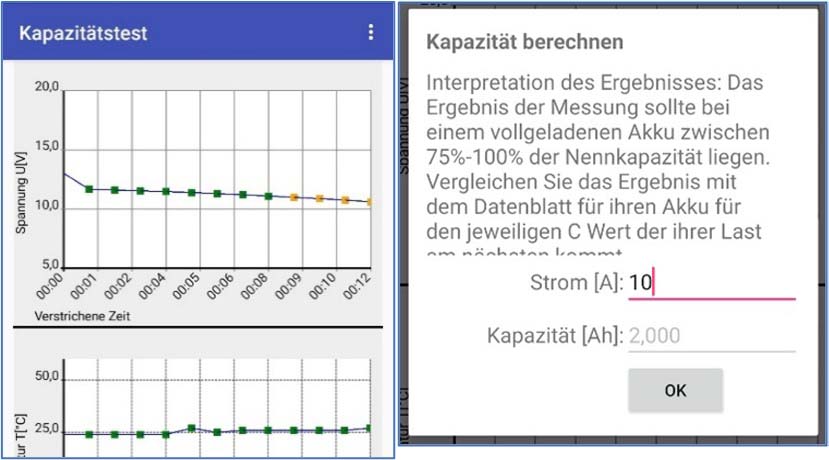

Da die SMART-Technologie ein Bestandteil der Batterie ist, speichert der SMARTLOGGER ununterbrochen Betriebsdaten zu der jeweiligen Batterie und liefert via NFC alle notwendigen Daten, um eine Aussage über den Handlungsbedarf treffen zu können. Die Speicherkapazität beträgt bis zu 10 Jahre.

Die aktuellen Batteriedaten und Aufzeichnungen werden über die SMARTBATTERY COMPANION APP und eine NFC-Schnittstelle direkt auf jedes Android Telefon oder NFC-Lesegerät übertragen und ausgewertet.

Die SMARTBATTERY–Technologie bietet erhebliche Kostenvorteile gegenüber einem traditionellen BMS mit der Einschränkung, dass die Daten vom Techniker mittels NFC abgeholt werden müssen und ohne Nutzung der Schnittstelle nicht im Netzwerk zur Verfügung stehen.

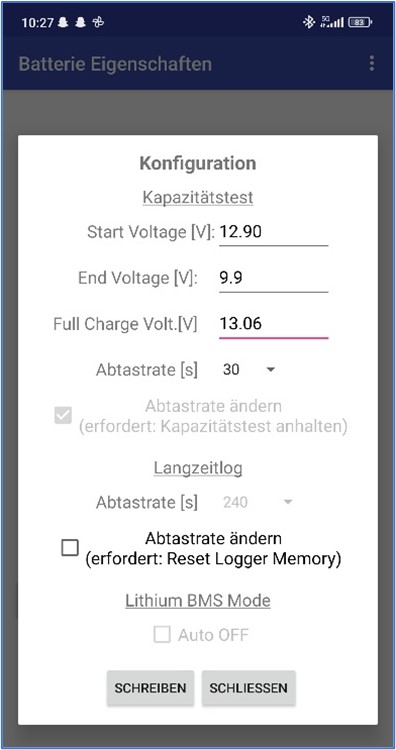

Kapazitätstest

Mit dem Kapazitätstest kann nach einer Entladung errechnet werden welche Kapazität dem Akku entnommen werden konnte.

Funktion des Kapazitätstest:

Einfach den SMARTLOGGER mit dem Akku verbinden und bei Kapazitätstest in der APP auf „START“ klicken. Es kann konfiguriert werden ab welcher Spannung automatisch eine „Entladung“ erkannt werden soll (START Voltage) und wann die Entladung als beendet angesehen werden soll (End Voltage). Ebenso kann konfiguriert werden, ab welcher Spannung der Vollladezustand wieder erreicht ist (Full Charge Volt) und mit welcher Abtastrate dies aufgezeichnet wird (60, 30, 10, 1 Sekunde). Der „Lithium BMS Mode“ berücksichtig die Besonderheiten von Lithium basierten Batterien deren internes BMS zeitweise die Batterie abschaltet (bei zu hoher/geringer Last, Temperaturproblemen etc.)

Bei Erreichen der eingestellten Grenzwerte wird der SMARTLOGGER / SMARTBATTERY die Aufzeichnungsfrequenz erhöhen und die Entladungsaufzeichnung beginnt. Nach Ende der Entladung errechnet die APP die entnommene Kapazität in Ah von Beginn bis zum Ende der Entladung.

Für weiterführende Analysen können die Batteriedaten in einer Datei über Standardtechnologien wie Mail oder Messenger-Dienste von ihrem Mobiltelefon exportiert werden.

Batteriedaten automatisch aufbereitet für ihren Batteriereport an den Kunden

Die Batteriedaten können per „SMARTBATTERY EXPORTER“ – einem frei verfügbaren Windows-Programm von der GENEREX-Website (SMARTBATTERY | Generex) in eine EXCEL Datei umgewandelt werden

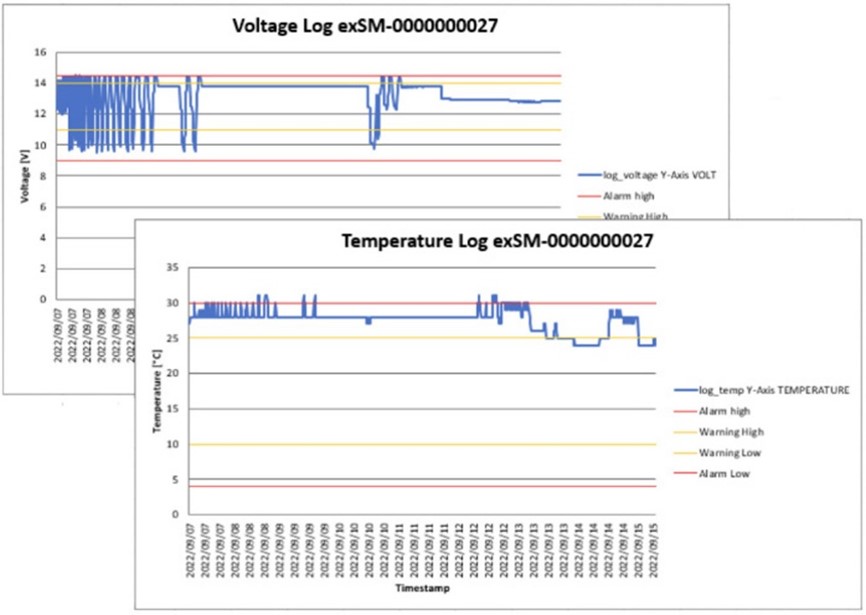

NEU ist ein Service ab Ende 2024 der diese Konvertierung automatisiert und die Datei binnen Minuten in konvertierter Form wie im Beispiel rechts zu sehen zurücksendet.

Der Spannungs- und Temperaturverlauf mit den eingestellten Grenzwerten wird in dieser EXCEL-Grafik dargestellt und lässt Tiefentladungen oder andere Grenzwertverletzungen über die gesamte Lebensdauer der Batterie leicht identifizieren.

Black Box oder Fitness Tracker: Mit der SMARTBATTERY erfassen Sie den Weg einer Batterie ab Werk „von der Wiege bis ins Grab“ und erfüllen die kommenden EU-Richtlinien bei der Nachverfolgbarkeit von Problemstoffen.

Was haben wir sonst noch mit der SMARTBATTERY Companion APP 3.0 verbessert?

- Namensänderung "SMARTBATTERY Companion": Der Name der APP wurde geändert – zusätzlich unter diesem Namen findet man im GOOGLE Playstore die APP nun auch unter den Suchbegriffen „iBACS“, „SMARTBATTERY“ und “SMARTLOGGER“ oder auch schlicht „GENEREX“

- Der Welcome Screen zeigt nun an, dass diese APP der EU Richtline für eine BatteryPassport entspricht. Ob diese Funktion „aktiviert“ ist oder nicht, hängt von der Version des SMARTLOGGERs ab, die Variante mit „Krokoklemmen“ für den Batterieservice Techniker hat den Passport nicht aktiviert.

- LOG"-Funktion wurde verbessert um sehr große Datenpakete >200k/>10 Jahre verarbeiten zu können. Einstellung der LOGRATE kann nun individuell verändert werden. Zusätzlich wird beim Einlesen eines Akkus nun immer auch sofort das Basis LOGFILE abgeholt.

- Ab Ende 2024 wird der SMARTBATTERY EXPORTER von der GENEREX-Website auch automatisch alle Daten nach Microsoft EXCEL konvertieren und erzeugt automatisch EXCEL Grafiken, die in einem Servicebericht direkt verwendet werden können. Über den SHARE Knopf können nun sowohl einzelne Batterien versendet werden also auch die gesamte Gruppe.

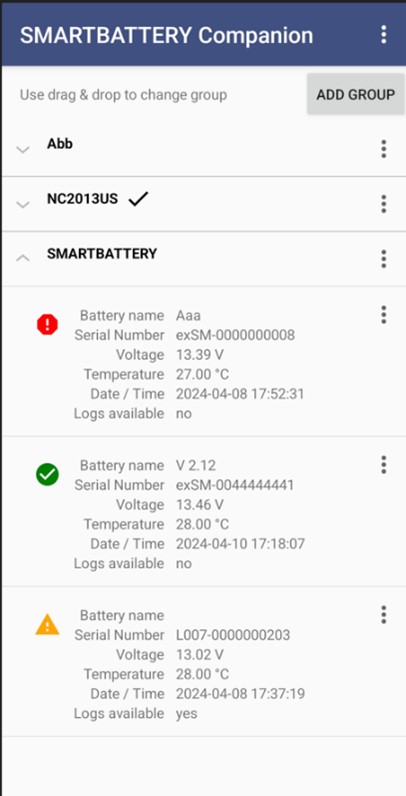

- BATTERIE-GRUPPEN: Die Funktion "GRUPPE HINZUFÜGEN" erstellt für jeden Kunden eine eigene Batteriegruppe, in der alle Messergebnisse gesammelt bzw. per Drag’n’Drop in andere Gruppen verschoben werden können. Dies erlaubt es mit dem Android Handy auch größere Batterieanlagen für unterschiedliche Kunden auf einem Mobiltelefon zu verwalten – solange, bis die Daten exportiert und in Batterieberichten verarbeitet wurden. Zusätzlich wurde die Sortierung verbessert. Es können nun STANDARDGRUPPE angelegt werden in der alle neue eingelesenen Batterien automatisch eingefügt werden. Die zuletzt eingelesene Batterie wird optisch hervorgehoben und das Löschen kann nun Gruppenweise und einzeln erfolgen.

- Individuelle Batterieschwellwerte: . Der Anwender kann nun eigene Schwellwerte definieren ab der sich die Anzeige der „Batterie“ von grün auf orange/rot sich ändern soll.

- Individuelle Batterienamen : Ab HW 2.12 kann jede Batterie einen individuellen Namen erhalten und die Anzahl der Entladezyklen wird ermittelt und angezeigt

- Akustische Lese/Schreibbestätigung: Beim Lesevorgang wird akustisch nun gemeldet ob dieser erfolgreich war oder wiederholt werden muss. Die Fehlermeldung am Display muss nicht mehr erst gelesen werden, der Ton meldet bereits ob erfolgreich oder nicht.

Zurück zum